Tools and Tool Placement FAQ

compiled & edited by Kristian #562

Please read the Disclaimer before attempting any work in this FAQ.

Updated 15 August 2004 by

Nate #1379

Tools

for General Maintenance

Tools

& Parts for Trips

General Parts

Tool Humour

Tools for General Maintenance

What Stock Tools does BMW Provide ?

Allen Keys, Spark Plug Socket,

Couple of Dinky Spanners, Reversible Plain/Philips Screwdriver.

For the GS See this Pic, from

Gerry #951

What additional Tools should I buy to

fix my Bike?

The Classic REQUIRES only one

SPECIAL tool, the alternator rotor puller, to tear the entire

bike into little tiny pieces. That's about $24 and hardly worth

paying postage to ship around. There is a special bolt required

to hold the crank when doing cam stuff. But that costs under a

dollar, and you can make one by grinding the end of a normal bolt

for a rounded "point." To completely tear down a

Classic, you'll need a pair of 22mm sockets, a 30mm socket, a

26mm socket (or 1-1/16") and probably a 30mm combination

wrench, too. A set of 6, 8 and 10 mm Allen sockets and a ball-end

5mm Allen key simplify and speed up the job. All the regular,

normal tools will be needed. Assorted metric wrenches (17 and

19mm combination wrenches are critical), a selection of

screwdrivers and pliers and, of course, a hammer. Having

1/4", 3/8" and 1/2" drive socket sets with an

assortment of extensions will make you happier while the work is

going on. But you COULD do it with just one set and a lot of

cussing.

If you plan on dropping the motor,

first get a pair of 14mm bolts at least 100mm long. They make it

SO much easier to keep things in line when pulling the swingarm

bolt. And they make getting the motor back into position at the

swingarm a snap. Otherwise, you'll be wrestling with those dammed

nylon swing arm washers for what seems like forever (Dab of

grease helps!). Flash #412.

Choose just what YOU need:

- Torque Wrench

- Good Metric Socket Set

- A SkewDriver is a VERY useful

Tool if you have a carbed bike. Refer Idle

Mix Screw for why.

- If you were a real BMW rider,

you would just slip a credit card in your tool kit and

forget the rest of the stuff. (In my case, I have added

an adjustable wrench, a tire pressure gauge, a rag and

hand cleaner, one of those little valve core wrenches,

electrical tape and a small knife.) Richard #230.

- I have added REAL 8 and a

REAL 10 mm combination wrenches. I threw away that p.o.s.

factory-supplied screwdriver and stuck in one what has

two nut drivers and large and small + & - tips. I

keep my crank stop bolt in there, too, and some LocTite.

I also carry four t-handle Allen's. Don't recall the

sizes, but they fit the tank and sidecover screws and a

bigger one for the engine case screws and a REAL big one

for one of the honkin' suspension bolts. I also have a

5mm Allen with a ball tip on one end. I think I REPLACED

all of the p.o.s. factory Allen's, too. I added SMALL

Excelite +/- screwdrivers. I have a set of REAL open end

wrenches from 6 to 19 mm. I have some other stuff in

there that I can't think of right now. And I have some

other stuff that I carry when I tour (that doesn't live

in the toolkit under the seat or in the tail section). I

must say that a set of 3/8" drive metric Allen keys

is THE TICKET when doing major service to the bike. That,

and I put 4 t-handle Allen's in my under seat tool kit to

carry ALL the time. AND... a 5mm ball point Allen is THE

tool to add to the tool kit. Flash #412

- Exhaust Gasket Replacements. Get a 13mm box end wrench. A

socket won't work. An open end won't work. Get a BOX end

wrench. An open end will round off the corners of the

cream cheese material used to make the fasteners. The

stock stud nuts are made of cream cheese and

extraordinarily cheesy. You may want to replace them with

some Japanese exhaust nuts that you have lying around.

Perhaps slather everything with Aunti Seize (she didn't

mind). (That’s Anti-Seize to non-native English

Speakers - ed). Flash #412

- Here's a link to the IBA site

for Ron Major's toolkit. Its been used as a reference for

on-road duty for several years now. Just needs adapting

to be bike specific. Shawn #1051 Maine. http://www.ironbutt.com/aow/major_tools.htm

- Pulling the Flywheel. The

Flywheel Puller Tool 12 5 510 is the BMW tool number.

This number is from the GS manual, but from the pictures

of the tool and motor, it's likely the same.

- On the classic, here are a

few socket sizes you may need:

- Swing arm removal, 22mm X 2

- Countershaft, 30mm

- Rear axle, 19mm and 24mm

- Steering head, 32mm

- Since most kits don't go

above 24mm and most also don't have 2 22mm sockets, you

have to buy a few extras. Each is about $4-6 at sears.

Mark #403

- Here is a Christmas gift

suggestion for someone who likes tools and has one of

everything. Torq-it Products ( www.torq-it.com/products ) (1-888-876-9555) makes a cute

3/8 inch palm ratchet wrench called the Torq-It Speed

Driver. It is about 3 inches in diameter and about one

inch thick and has a pull-rope, like you use to start a

lawn mower. You loosen the bolt or screw with your hand,

or a regular ratchet wrench if it is too stubborn, and

pull on the rope once or twice and the fastener spins

off. Is particularly useful for removing and installing

F650 body parts. It serves the function of a cordless

screwdriver or air ratchet, without the charging or

air-compressor, and takes up much less space in the tool

box. It sells for about $20. My daughter brought me one

for my birthday and I have found it very useful. I

recommend it for gadget and tool lovers.

- Torque wrench guide: I have

heard that Snap-on tools are more durable, but they are

also far more expensive than Sears. If you were running a

garage and using your torque wrenches constantly on a

daily basis, it might make sense to invest in Snap-On.

Proto also makes some fine tools. I found this link very

helpful, and would suggest you check it out before buying

anything. It's a quick read: http://www.rdfrantz.com/rdf/TorqueWrenches.htm. Mason #631.

- I suggest 3 Torque Wrenches 1

inch pound, 1, 5lbs to 50lbs and 1, 35 to 150 lbs . Why?

Because the accuracy can be less than desirable with a

wrench that covers to much too much range. V V.

- A Voltmeter.

- Possibly a Micrometer.

- Refer also to individual

FAQs.

For the GS Only:

- Sears also sells regular

drivers with Torx ends. Same as a screwdriver/different

end of course. There are four sizes you'll need at least

for a '01 GS Dakar:

- Item Sears part

- Torx T25 41476

- Torx T30 41477

- Torx T40 42665

- Torx T45 42666

- The first two are the

screwdriver-types and are for the smaller bits. The last

two are the larger ones and are excellent for use with a

torque wrench. I'll supplement these with t-wrenches one

of these days but these are a good starter set. Gerry

#951

- Torx Wrench. I have been very

happy with the set on this link. http://www.wihatools.com/364serie.htm TomO-AR 650GS;1150GS Adventure.

- I added a 3-4mm Allen key

(not sure) to the tool kit for the air filter. db (00

GSD) au.

Feedback:

- ..we have added

"T"-handle / ball end allen tools (about

10" long w/ red handle) in #3, #4, #5, and #6 --

made working on the bikes much faster! We don't use for

serious torquing (sp?)/tightening, just helps get the

bolts out much faster :-)

#3 is for windsheild and fairing screws

#4 is for the side panels and a couple of fairing screws

#5 is for engine and much of the frame -- most common

size

#6 is for chain tensioner and larger frame bolts

#10 and #13 wrenchs with ratchet built in on one end will

also speed things along..

ultimatejourney

Special

BMW tools

Davidhpark, #711

Subject: Special BMW tools

In re-reading/reviewing the BMW service manual for the F650GS I

decided to extract the BMW part numbers for the tools that they

recommend using (why they can't simply provide a list at the end

of the manual is beyond me). I submitted them to my local dealer

to get pricing/availability. These are all "special

order", must be prepaid and there can be no returns. That

being said, I found it funny that some of the stuff wasn't

available (at all) in the US and some of the tools that they list

for valve adjustment aren't available at all (i.e. no longer

available either in US or Germany).

- Countersprocket puller,

BMWNo.88886 00 8 400 = $52.25 available in US

- Oil drain guide, BMW No.

9088611 7 511 = $61.50 available in US

- Hose pliers, , BMW No.

9088617 5 500 = $115 available in US

- Valve-clearance adjuster,

BMWNo.9088611 7 501 = $235 available in US

- Thruster, BMWNo.9088611 7 503

= no longer available

- Shaft, BMW No. 9088611 7 502

= no longer available

- Clamp block, BMW No. 9088611

7 504. = no longer available

- Magnetic holder, BMW No.

9088611 7 505 = $44 not in stock, Germany may have it.

- Hose clips, BMW No. 9088613 3

010. = $10.40 available in US

You can get by for most

jobs, without any of these Tools (See individual FAQs). You DO

need the BMW Flywheel Puller though. Flash#412, Kristian #562.

Generic Flywheel & Clutch Holder

Tools

- http://www.denniskirk.com/powervendor/details/detail.asp?serverid=OffRoad&PartNo=28288 Designed to hold clutch baskets,

flywheels, gears, sprockets, etc. Jaws open 5"

Medium-carbon steel with hardened jaws. Flywheel/Clutch

Tool Part Number 28288 Manufacturer Motion Pro Type

Engine Tools $29.99 In Stock

- http://alba.buyol.com/Item/PC005018.htm

Clutch Inner

Hub Holder - Motion Pro [PC005018] shipping weight: 1

LB This tool is used for holding the inner clutch hub

while you loosen the nut holding it on. It is very

helpful during motor rebuilds. This tool can be used on

most any dirtbike or atv. We highly recommend this tool

if you plan to install a Hinson clutch basket. Also good

for pulling teeth. Every good motocross mechanic should

have one of these in their tool kit.

$30.99

- http://www.motionpro.com/servicetools_3.html Clutch Holding Tool The Motion

Pro Clutch Holding Tool is made from medium carbon

steel with hardened jaws. They feature spanner pins and

the jaws open up to 5" wide. They are ideal for

holding clutch hubs, flywheels, gears, sprockets, etc.

Part Number 08-0008 Sug. Retail: $ 30.30

Specialist

Tools

Axle Wrench: You can replace the axle wrench

with one of Scott's tools (smaller/multi-function). You need a

24mm for the rear axle - options for the other end are 19mm and

17mm.

BMW Valve Shim Removal Tool: When talking to

the tech's (Jim) at CalBMW we were discussing valve adjustments

on the F650GS/Dakar. Apparently they have a special tool that you

can use which makes the job a 5-10 minute job as you don't have

to take off the cam chain, etc. You bolt this appliance on

to the top and then with a few turns and such can take out and

replace the shims. It's about $350 and I'm seriously considering

getting it. Opinions? Would be nice to save time and not have to

mess with parts of the bike that don't need to be disassembled.

DHP #711

The Overwhelming Opinion is SAVE YOUR MONEY. (See

the GS Valve Shim FAQ): Here's the feedback:

- Seems like a lot of dough for

something that doesn't get used a lot... But if you just

won the Lottery and have money to burn, go for it.

Seriously, BMW is notorious for charging a premium for

their tools. Have you seen it? Is it something that you

could reproduce easily and inexpensively? Do you know if

it works for the Classic, or just the later model head?

Inquiring minds. Harl #380

- You must be checking your

valves quite often ;-) For $350, you could just let

someone else do it a couple of times, but doing it

yourself is of course more fun. If you got the money go

ahead and buy it, personally there are so many

accessories I'd buy before this tool. On the classic it

is just another 10-15 minutes of work to loosen the nuts

and zip-tying the chain. IMHO. Spakur#1117.

- Take a few pictures of it and

post them where folks can SEE 'em. THEN let's discuss it.

Nearly EVERYTHING can be fabricated for a WHOLE lot le$$

than BMW.

Flash 412 (CO)

- This tool is very involved

and takes a lot of time to setup and use. It really is

just as easy to remove the cams, which is not all that

involved once you know how. Besides, shim adjustments are

not that frequent once set. BUT it would be nice to

create a tool library listers could rent or borrow from

to do specific tasks where special tools are involved. If

a hundred people chipped in $25 each you could buy a lot

of tools which could then be mailed around as needed.

echo

- Now I know why the techs

never had to sweat getting the cam chain tensioner bolt

off my bike! If your GS has ABS this tool might just be

worth having because without the tool you have to remove

that bolt which is nearly impossible to do on bikes with

ABS. bg#1002

- I have used this tool and it

won't work on the cam chain side valves. It is fine on

the sparkplug side. The BMW school for BMW Certification

teaches you to remove the cams!! Save your money. Steve

1130 Or

Tool Tips and Tips for Tool-use:

by Mal #1011 & Various Authors

For years I've been using some

dodges I've not seen on the web. I thought I'd share them

with the Gang. Here I'll scratch the surface with a couple..

Allen keys:

Take a set of regular Allen keys and cut off at the turn so as to

end up with straight keys. Also the short lengths (not shown) can

be used the same way.

SEE Cut-Offs1 and

Cut-Offs2.

1. Can be used in many ways in a cordless

drill/driver (handy for taking all those screws that hold the

bodywork and engine covers). ALWAYS start screws in the thread

the usual way as the drill/drivers are too fierce. SEE DrillDrvr

2. Can be used with sockets. I use Blu-Tak, the

tacky plasticine for sticking paper on billboards etc To hold

them in. SEE Socketkey

Allen screws with thread locking

compound on them or seized:

- Heat them without damage.

Brake disks/rear wheel sprocket etc. The key hole will

round off most of the time if attacked cold. The trick is

to heat the compound and make it soft so it stops doing

it's job. So buy cheap set of keys for the job.

- Place the long end of the key

in the hole. Heat it with a blowlamp or electric hot air

gun. A soldering iron would work by replacing the bit

with the Allen key. Take your time , it will take a while

for the heat to get down the key and into the screw.

Every few minutes take out the hot key ( Remember it's

HOT ) and GENTLY try to undo the screw with a regular

key.

- SEE HeatKey1

Fork Top

Threads:

These are a fine thread and can get crossed up. If

the sockets are held as in ThreadFeel,

this way the top stays square. With the ratchet in the undo/anti

clockwise (AC) direction - press down and turn AC . You will feel

a jump as the thread on the top cap meets the end/start of the

threads in the stanchion. Ease out the top cap and let it sit in

position on the spacer. Set the ratchet clockwise (CW) to

tighten. Press down as in ThreadFeel

and the threads will be lined up start to start.

Spring Removal - Installation

by Flash #412

Try placing coins in between the

spring coils to extend it. For spring removal, I would start with

the bike on the centerstand, as this will extend the spring to

some extent. Don't try to extend the spring to add more coins,

but rather try to flex it side to side. Eventually, when enough

coins are inserted, you should be able to retract the centerstand

and the spring should be extended enough for removal.

Listening to Engine Rattles

by Flash & Richard #230

Use a screwdriver as a stethoscope

to help track down the location of the rattle.

Torque

Wrenches

- Don't leave your clicker

torque wrench set for 100 NM, it will knock the thing out

of adjustment. These type of torque wrenches must always

be reset to 0, once you are finished using them. I assume

that the spring tension that makes the wrench work will

get sacked-out if it is kept tight all of the time. This

will make your wrench click at too low a value. All of my

clicker wrenches came with a warning to always reset the

tension to zero before putting the wrench away. Richard

#230, Pacifica.

- Richard is correct on this

one - torque wrenches are subject to wear, abuse and

damage. They should always be reset to zero when not in

use. Generally speaking, they should not be lubricated,

used as a breaker bar, or used to remove bolts. Quality

ones can be sent for recalibration. Todd #389.

- Since I'm off to get my

torque wrenches re-calibrated, thought I might mention it

here. For those of you who tighten up bolts to specified

torque values, you should get your torque wrenches

recalibrated every couple of years. They can (and do)

start to vary either direction. One other point: Torque

wrenches are calibrated for certain temperature ranges,

so if you're out in the unheated garage and its 10F

outside, you might want to bring your torque wrenches

inside for a few hours before use. Nate

- While at it, I just spoke to

my Dad (very smart man) about torque wrenches. He said

that for the type that makes the "click" sound

(what are they called?) to not over torque with them.

Apparently, they have the reputation for losing their

calibration quickly. According to him this is in large

part because people over torque with those wrenches,

thinking a few more lb-ft or Nm can't hurt. You're

supposed to stop at the click, if you want more, adjust

for more and go to the click, or use a different wrench.

its_xls

- http://www.geocities.com/motorcity/downs/3837/torqwren.html

- Next.

Torque:

Metric Converters

Penetrating

Oils

- This past weekend I decided

to remove the Staintune exhaust from my classic F and

re-install the stock pipe. Except I couldn't get the

crossover pipe to separate from the header. I took the

header/crossover off the engine and tried a chain wrench,

heat, and wrestled with this for hours. Finally gave up

and drove to the nearest auto parts store and the pimply

faced teen-ager behind the counter handed me a can of

B'Laster penetrating catalyst and said "this stuff

is fantastic". I said to myself ya, right. what does

this kid know but for five dollars I thought it worth a

try. I sprayed the stuff on the junction of the pipe and

muffler and let it sit for 5 minutes and the two pieces

separated easily. Richard 424, Oregon

- If you're talking about

PBlaster--it is the best penetrating lubricant I've ever

used to separate frozen parts and loosen frozen

nuts/bolts. Nate

- My favorite is marvel mystery

oil that comes in a red can. The stuff is fantastic. I

keep an oil can loaded with it and use it all the time!

It is great on rusty parts. (I have done work on fords so

I know!) Don - Rochester, NY

- ANTI SEIZE. Now ya know why

ya should always use anti seize on exhaust

connections,,,,years later they just slide apart,,,,,mike

mike410(Iowa)

- I like Marvel Mystery oil

too. Smells great! I don't find it to be as good as

PBlaster for loosening nuts/bolts. I like it for cylinder

lube (engines which aren't going to run for several

months), as a cutting oil and during engine/transmission

assembly (along side assembly lube). I also add it on

occasion to a tank of gas in my old (1967) Land Rover to

lube the valves and valve seats. (BMW content: BMW owned

Land Rover for about 7 minutes once). Nate

Getting

Stubborn Nuts Loose

- USE a SIX POINT SOCKET - NOT a 12

Point one.

- Some bolts cannot be undone

alone - you may need a strong and beefy assistant to

steady the bike and hold the brake, and you'll need a

proper breaker bar (extra long socket wrench). If it's

assembled with Loctite 243, use of a heat gun (or careful

use of a propane torch ON THE NUT NOT THE SURROUND) may

be necessary. If a previous mechanic mistakenly used

Loctite 648 (per OEM) or Red Loctite, serious heat will

be REQUIRED, not optional.

- The next level involves use

of a large commercial air impact wrench for : removal,

however, use of heat is still recommended, as if there is

Red Loctite in there and it's not softened with heat, you

can break things or rip the threads right off the

assembly. (Not likely in this case with a hardened crank,

but you never know.) If heat AND an air wrench won't get

it... eww. If you have the proper wrench setup, don't be

afraid to get the nut up to 100 degrees centigrade

(212F), maybe even 225F. No higher or you start to : ruin

seals, and if it's the Flywheel Nut, the magnets in the

flywheel don't like excessive heat either. Best to start

off organized, all tools in place, a dry run, quickly

apply massive heat on the nut with precision, remove and

cool down with a fan.

- Personal Impact wrench. I

have a cheap electric one that is sold for removing tire

lug nuts and plugs into a car cigarette lighter

receptacle and supposedly produces about 200 pound feet

of torque. Maybe you could rent a real one at a

rent-a-tool shop. In the mean time, soaking the nut with

penetrating oil overnight couldn't hurt. Richard #230.

- Finally Drill a set of small

holes in the nut, all in a row. Then take a cold chisel

and a BFH and break the nut off. Flash #412

- What's a BFH? A BIG F*****N

Hammer.

- Be careful when taking the

sump bolt out off the bottom of the bike. I first tried

with a socket wrench on the left side of the bike. If you

have changed the oil before, you know how difficult it is

getting that bolt off. Anyway I yanked really hard once

just to have the bike lurch forward and teeter on the

center stand. Luckily it fell back on the stand. If it

hadn't, it could of been ugly. I was in the garage laying

on the floor and caught between my car and bike. Anyway,

the lesson learned is to unscrew the sump bolt on the

right side. At least on my GS. Bobcatou '02 GS

#1157

- Try to not "yank"

on bolts--this leads to rounded bolts, broken off bolt

heads, cracked sockets and motorcycles, engine blocks,

transmissions, etc slipping off their supports. If the

bolt won't go, try these things: 1. Put a cheater bar on

the socket handle (i.e. a longer arm for greater torque).

I've had up to 14 FEET of pipe on a socket before (was a

nut on the bottom of a 6 foot bush hog). Gentle firm

pressure on a longer arm will get more done with less

damage than yanking on too short of a socket handle 2.

Blue wrench (i.e. heat). Heat gun, propane torch etc will

often crack the points of adhesion. Heat the bolt

directly (to avoid damaging the surface the bolt goes

into). 3. PBlaster (or other penetrating oil) soak, leave

and drink beer, then come back, test. Repeat as

necessary. Yanking will cause you grief in the long

run. Just say no. Nate

- 14 feet Wow! I have used some

long cheaters before maybe 6 feet on the axle nut of my

VW Bus one time. Then again sometimes I use long ones at

work on ships. The ultimate for me was removing the top

and bottom fittings on high-pressure air flasks (5000

psi) for the Navy. I set up a 2-foot piece of 10 inch I

beam standing on end and welded it to a steel table 1

inch thick. I put the air flasks laying on there sides in

special clamps to hold them down with one end pushed up

against the I beam. At the other end another I beam and

in-between a 1 1/2 drive socket (about a 4 inch nut) on

an 1 1/2 drive air impact gun and used a portapower jack

to hold pressure on the impact gut against the nut. What

a racket it would make but it worked very well. Others

used heat and a slugging wrench but that would take as

long as several hours on one flask. My method did several

flasks in an hour. I also did not like applying heat for

a number of reasons. The seal was some sort of Teflony

thing and made nasty smoke when heated and the flask in

my opinion should not see this much heat because of the

pressures involved. Will in CA

- Another basic lesson: RIGHTEY

TIGHTEY---LEFTY LOOSEY. That is true 99%of the time

(except with left hand threads). bmwterrien2. "don't

force it- or it will break" Steve #11059 in MA

- In reading Bryan's post a

second time, I believe his point was that it's best to

recline and work from the right side of the bike, so that

the force used to loosen the sump bolt is transmitted

backward toward the center stand, rather than toward the

front of the bike as can be when working from the left

side of the bike. I also once almost pushed my bike off

the center stand in this way (back when it had a center

stand before I put on a Touratech suspension kit). I

don't know if Bryan meant he literally yanked on the

wrench, but the bike can be rocked forward simply with a

very strong, even pull on the wrench from the left side

if one is pulling toward the front of the bike. Mike #926

- When you are going to be

working under the bike like that, bungy or tie the front

brake lever to the handgrip so the bike can't

accidentally roll forward off the centerstand. Bonnie

#1158 northern Illinois '02 F650GLA.

- I just got around to reading

my June issue of Motorcycle Consumer News. They tested

three tools for removing stripped nuts. They highly

recommend the Sears Craftsman Bolt-Out set(part no.

952165) at $59.95 for a set of 10-19mm sockets. They said

that it was able to remove every nut that they tried. The

Vice-Grip 10L W-02 fits nuts of 15-28mm, at $14.90, was

partially successful at removing their test nuts. The

Harbor Freight Universal ratchet set at $11.99 was

useless. Richard #230

Cheap

Maintenance Tips

- Here are some random tips:

(Richard #230)

1. If you have plastic side panels on your bike that plug

into rubber female grommets, they can be hard to push in

and even harder to pull out of the grommets. Coating the

rubber with Armor All, or the equivalent, will make it a

lot easier to push them in and pull them out without

breaking the plastic male appendage and leaving it stuck

in the female attachment.

2. Placing a small rubber O-ring around the back of body

panel screws will help to keep them attached to the body

panel when you remove it from the bike. That way they

will stay with the panels and you will not have to dump

all of the little screws into a can and dig through them

for the right size when re-installing the panels. It also

prevents you from kicking your screw can and watching the

screws travel all over the garage, some of which will end

up stuck into your tire, while you will find the rest in

the middle of a spider's nest, or stuck to the sock you

lost last year.

3. For those of you that have bikes with uncovered slots

in the clutch lever and lever housing (which is used to

install and remove the clutch cable from the lever), you

can cover the slots with small pieces of black electrical

tape to keep dirt and water out of the clutch lever pivot

area and clutch cable ferrule.

- Next.

Bike Storage Tools

- I can finally park my car in

the garage. I just bought the Telefix Motoboy. It's a

center stand platform on wheels that allows you to move

your bike very easily in tight spaces. I think these are

popular in Europe but I haven't seen too many of these in

the U.S. Now I finally have room to park my car in the

garage. Warning: until you get used to it, it is very

difficult to place it on the dolly since it is a little

higher off the ground than the ... ground. You don't get

as much leverage when propping up the bike on its center

stand. I think I'll try rolling the back wheel on a board

to raise the back higher off the ground to see if that

helps. Here is a link if anyone wants to see what it

looks like. http://www.bmwbobs.com/store/tools/Telefix.html. esef

- A cute device, but it looks

like you need a centerstand to use it. Marketing types

say that centerstands are too practical and will not sell

motorcycles, so lets stop making bikes with those

ungainly things attached to them. After all, our

customers would not want to get their hands dirty to oil

a chain or change a tire (would they?). (Hey CS, where is

your centerstand?) Richard #230: 1997 Funduro, 2002

R1150R, 2002 Yamaha YZ1, 1993 Honda CB750 - Pacifica, CA,

USA

- Here's the

"high-tech" device that I use to get my 99 F650

up on the center stand---namely---a one inch thick piece

of board. I slide it up tight to the rear wheel, bump the

bike back on it and then it pops right up on the center

stand. I have the lowering kit on my bike and the center

stand has been made a bit shorter so some of the leverage

is lost--thus I can't get the center stand to work

without the board. I guess if I weighed a lot more this

would not be a problem. When I take the board out and use

it in a public parking area, it has drawn some very

strange looks!!!! Bill No. 391 Las Vegas

Micrometers:

Metric

http://www.utc.edu/Faculty/Harold-Climer/metricmic.pdf

Standard (not really

"standard", since THE standard is the metric one)

http://www.precisionmeasure.com/microm1.htm

http://www.formtechservices.com/dstuff/bookstuf/p26.micrometers.html

Spoke

Wrench Information

General

Spoke Wrench Info

by Marty #436-Chicago-97 F650F &

Seacuke, #1214, F650GS

I measured my Classic spoke nipples...about

0.240" (close to 6 mm). My old set of spoke wrenches say

that it's between a #9 (sloppy fit, but works) and #10 (no fit,

and I have no clue what the numbers convert to...). Personally, a

4" crescent wrench works for me in a pinch.

So I finally got a spoke wrench (Rowe Spoke Wrench), and discovered that the size '3' is the proper

(I should say 'properest') fit. This #3 didn't mean much to me,

but I did find this chart which

seems to maybe make some sense. If indeed this is 3 AWG, that

would put our diameter at 5.816 mm, and in eyeballing the tool

with a ruler, it does indeed appear to be just over 1/2 a cm

(5mm) wide at the '3' size.

So I guess what I'm saying is that I'd believe that the threaded

end of the spokes on our wheels measures somewhere's around 3

AWG.

Reviews of FAASTCO's Spoke Wrench

Fasstco Spoke Torque Wrench

Price (MSRP): $119.00

Optional heads: (5.0mm, 5.6mm, 6.0mm, 6.2mm, 6.3mm, 6.4mm, 6.7mm,

6.8mm, 7.1mm, and spline drive) $9.95 each

Will Pattison's Review

Ok, let's get the disclaimer out there right from the start -

I am not a professional wheel builder. I've been riding, racing,

and wrenching on my own motorcycles for 20 years, but it's not

how I make my living. While I've split my share of cases and done

top ends by the dozens, I only recently decided to tackle wheel

building. As a mechanical engineer, I can readily accept that

every spoke in a wheel should have the same torque, and that

there is in fact an ideal setting. I figured that the Faast Co.

Spoke Torque Wrench would put some science into the art of

determining exactly what that value should be. I also imagined

that it would turn a newbie wheel lacer into a pro in short

order.

In a word, wrong. The first task I chose to try the wrench was a

rear wheel. I already had everything pretty snug, and the rim had

less than 0.025" of run-out or wobble. I assumed at that

point that I could simply use the torque wrench to take them all

to the 100 lbs. mine is set at and be done with it. Big mistake.

After cinching up all 36 spokes I stepped back to admire my

handiwork and quickly saw that I was in trouble - the wheel had a

wobble I could measure with a yardstick! At that point, I did a

reset and finished the job by feel. As I expected, the wheel

loosened each time I rode the bike (yz400) for the first 5-6

hours, but since the spokes seated themselves, I've had no

issues.

I did give the wrench another chance, however, when I built the

front wheel in the set. Again, I found it to be less than

helpful. To be fair, though, I have to say I'm not sure that the

wrench is at fault. First, I believe that the same torque value

should probably not be used for both a front and rear wheel. Not

only are the spokes different diameter and the rims of differing

strength, but the abuse one takes is clearly greater than the

other. Second, in my short wheel-truing career, I've decided not

to use the resistance at the nipple to judge how tight the spoke

is. It seems that even with anti-seize on all the threads that

some of them want to gall a bit, which of course sets the torque

wrench off prematurely. That may be a manufacturing issue with

the spokes themselves (Buchanan in this case) or it may be my

choice of lubricant. I'm going to build the next one using plain

grease and see if it makes a difference.

Either way, I'd certainly like to hear the feedback of an

experienced wheel builder. I guess that until I did, it would be

difficult for me to recommend that any one else spend the $119.95

Faast is asking for this tool. I still believe that nipple torque

is important, but until I can reconcile that with actual

practice, I'm going to continue tightening them by feel and

sound.

Contacts:

Fasstco: http://www.fasstco.com

- Note: A Special Just For Honda XR.com Web Surfers! Faast Company has

extending a very special offer to web surfers of Honda

XR.com! They are offering one spoke torque wrench and one

head for $100! That's $30 off the normal price! Just

mention this review when purchasing your Fasst Company

spoke torque wrench!

- Please Note: Currency is U.S.

dollars. This offer is valid only on purchases made

directly from Fasst Company. Applicable taxes and

shipping may be additional. Honda XR.com is not

affiliated in any way with Fasst Company.

Tool

Feedback:

Genuine 2 by 4 with Snap-on

screwdriver to shim/adjust the wheel for doing the

bearings! (lift on 2 by 4 to lift the wheel to index fork

legs etc)

|

Craftsman jack stand holding up the

bike.

|

DeWalt light that takes the

rechargeable batteries, an excellent shop-light.

|

Valve Adjustment Box:

If you have take your shims out, keep track

of them. It is FAR to easy to mix them up, switch

buckets, shims can and will migrate/interchange/disappear

I made this box and chart for my 6K service but my valves

are all within spec (!). See the f650.com faq for more

shim explanation. I will have part #s for the

Triumph and Kawasaki replacement shims forthwith.

|

Rhodesian

Factory Tool:

After a long hard day working on the F650,

every Ridgeback needs a nice warm bath!

This is Cecil, my 115# Rhodesian Ridgeback

that helps with everything.

She grew up getting in the way of TY250s,

BMW Airheads and now is an F650 fan.

|

By Nate #1379

Hi all you fans of stripped thread holes.

Due to the unfortunate fact that BMW has chosen a cross between

pot metal and Cheddar cheese to use for the engine and

transmission cases (among other things), it may become necessary

at some point to repair a badly stripped out threaded hole.

There are really three options:

1. Fix it yourself

2. Take it to a machine shop to fix it

3. Buy a new part

While buying a new part will preserve the

originality of the bike, it is the most expensive option and

often requires additional disassembly to put the new part on. The

machine shop option usually is cheaper, but also requires

additional disassembly. Fixing it yourself is the least

expensive, and may not require any further disassembly. If you

choose to re-thread the hole yourself, you have a few options:

1. Drill the hole out bigger, retap and

use a bigger bolt (least appealing but fastest option)

2. Use a thread repair epoxy (only good for low torque,

non-critical threads)

2. Use an insert like Helicoil

3. Use an insert like Time-Sert

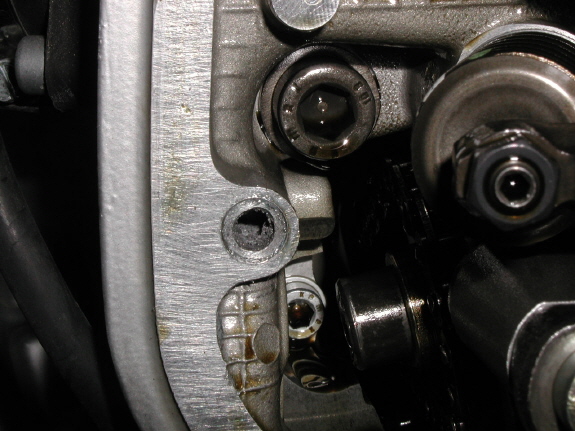

This is not an F650, but in fact a boxer

engine head (R1100S) where one of the head cover bolt holes has

been stripped out. Note that the hole is elongated as well

(towards 1 o'clock)

Although there are a few options in how to

repair this, I chose to use the Time-Sert method of replacing the threads to their

original dimensions (instead of drilling out to the next size up

bolt). The kit is expensive, but is significantly better than the

alternative Helicoil

since the new threaded insert cannot migrate down into the hole

and won't uncoil since the Time-Sert is a solid bush insert.

In general, the included instructions will

guide you well. But first things first. In order to use the

Time-Sert, one must have good, direct access to the hole, so that

drilling and tapping of the hole can be done completely square to

the surface.

Note that I have protected the rocker

assembly and timing chain from bits of metal by using a plastic

bag and cloth. One does not want the drilled and tapped bits of

metal to drop into the engine.

The first step is to drill out the old

threads using the included drill bit. Before I started drilling,

I used a small drill bit to determine how deep the hole was and

taped off the Time-Sert drill bit at that length to prevent

drilling too deep. I also spray the drill bit with WD40 away from

the open engine. The WD40 works as a cutting oil, but you do NOT

want excess draining into the engine or transmission oil because

WD40 will adversely alter viscosity. Be CAREFUL, the aluminum is

very soft and can be almost drilled by hand with a tap handle.

This next picture shows the counterbore in

the hole. The Time-Sert counterbore is set so it can't really cut

too deep. Again, I spray it with WD40 before boring, but do so

away from the engine oil.

Here, the hole as been tapped out. Be very

careful that the tap is completely square to the hole or else the

threads will be difficult to use (the hole will effectively be

oval). Again, I use WD40 before tapping. When turning the tap

handle, clockwise cuts the thread. After turning about 1 turn, it

is good practice to back off 1/4 turn (turn out counterclockwise)

to clear metallic chips from the cutting edge. Be careful to feel

for the change in resistance that signals the bottom of the hole.

DO NOT TURN ANY FURTHER when you get to the bottom of the hole or

you will damage the freshly cut threads. After backing out the

tap, blow out the hole to remove any leftover chips.

Some people coat the tap with grease to

increase catching chips. I have only done this once when trying

to tap a spark plug hole in place (ie head not removed).

The next step is to put in the insert and

turn it a few turns by hand. Although it is not mentioned in the

included instructions, I put a couple drops of locktite on the

outside surface to help ensure the insert locks in place.

This step involves driving the insert into

the hole. I coat the driver with a light machine oil (or engine

oil) instead of WD40 to prevent any chance of damage to the

insert threads. As you drive it into the hole, it will get

slightly more difficult and then get easier again. This is

because you are cutting the final threads and expanding the end

of the insert, locking it in place.

This is the finished insert. Carefully

remove the cloth and plastic to keep chips out of the

engine/transmission. I was able to retorque this hole back to

spec torque.

A couple of

explanatory notes to go with this:

1. If you have never tapped out a hole before, practice drilling

and then tapping the hole before trying it on your bike. Scrap

metal is cheaper than engine heads.

2. I only used the electric drill in a couple of steps:

A. Drilling out old threads--lightly

drilled, then used the drill bit in a tap handle

B. Counter bore--Used the drill without any concerns. The

counter bore will only cut the prescribed depth

C. Tapping the hole--NO ELECTRIC DRILL USED. I used a tap

handle (sometimes in a tight spot, an open end box wrench

will work if you are careful)

D. Installing the insert--NO ELECTRIC DRILL USED. Tap handle

only

Tools & Parts for Trips

What Tools should I carry on Long Trips ?

Q. Are

there any favourite tools that F650 riders carry in addition to

the stock tool kit?

A. It depends on whether you’re doing a Long, Medium

or Short Trip, or a World Tour.

Here is a

cross-section of opinions:

An

observation: tools and parts are a bit like insurance --

necessary, but hopefully never needed. e.g., if you never need

the extra tools and spare parts, they seem like a burdensome

luxury. But, if ever in a situation when you do need them, they

are the only thing that will suffice:

- The original Leatherman

Supertool: don't leave the carport without it.

- Hardwired accessory plug that

will allow access to battery with (a) your cellular phone

and (b) other pre wired goodies.

- Motorcycle specific jumper

cables.

- 70% polyester rag for

cleaning windshield. Keep it in,

- One of a half dozen quart

size zip lock bags so the rag does not collect lint or

excess moisture. Save the others for general purposes.

- Spare headlight and tail

bulbs (wrapped in bubble wrap so they do not get damaged

by banging around with the metal stuff).

- List of emergency telephone

numbers for you to call for help if necessary.

- Separate short list of

emergency telephone numbers for someone else to call if

you are injured and can't call for yourself (And keep it

where it can be found without blowing to the four winds

if you t-bone a tree or some other immovable object).

- Plastic mistletoe to hang on

your tail light if you are run out of a place you will be

better off leaving anyway. And finally,

- Carry a change of underwear.

That way, if you have to spend the night in the boonies

because you failed to carry adequate tools and parts, you

can enjoy the luxury of a fresh change before you begin

your walk out in the morning. And save the old ones to

use for a signal flag if a search party is sent

out.” Rick #725

From my

experience I have added to the standard tools:

- A little screwdriver, mainly

to help to take off the battery caps.

- A tube type hexagonal key 6-8

mm.

- Some spare electrical cable.

- Some hatbands (little and

medium size).

- Insulating tape, and what we

know in Europe as American Tape.

- A little box with spare bulbs

(obligatory to ride in Europe).

- A little punch, to help in

taken off the break pads.

- An adventure multiuse tool

all in one (pliers, scissors, clasp knife...).

And on large

trips:

- A spare clutch cable, only

the inner cable with a properly diameter trigger for

screwing down at the end of the cable.

- A manual air pump.

- Don't use the canned

Fix-a-Flat stuff. It doesn't work on tube type tires and

wheels. Use Slime and carry a pressurized Moto Pump.

All the above

mentioned have been used at least once, specially for the other

friends that I ride with. Unknown.

Feedback:

- Carry a valve core remover

(and a spare valve core). They rarely break, but if they

do, can leave you with an unfixable flat. They take up

practically no space. Marty #436

- Carry all the tools you

need. This is not a smart-ass answer. If you do your own

maintenance, you KNOW what tools you need to do

EVERYTHING you may need to do. If you don't do your own

maintenance, then likely you wouldn't know what to do to

fix what breaks anyway. In that case a cell phone and

credit card are the tools YOU need. I carry tire irons,

patch kit, pump and augmented tool kit. My valve caps

have integrated stem tools. The further I go from home,

the more I carry. Ask Prof if he thinks I carry too many

spare parts. ;-) Flash #412

- An electrical relay plus

female spades, wire and scotch-lock connectors are

useful. Just about anything electrical can be by-passed.

The Horn relay makes a good emergency fix for any other

switch (disconnect the horn). I ran nearly a thousand

miles running the fan through the horn button when the

radiator fan switch went. Electrical tape, multimeter and

pliers make life easier. Duct tape is a must. Andy Leeds

UK #982

- A compass stuck to the

wind-screen will be effected by the bikes magnetic field

and will only give an rough indication of direction. You

should get at least 5m (15 feet) from the bike to take an

accurate bearing. You could of course write yourself a

nice long correction list, but walking away from the bike

is easier and cheaper than GPS. Andy Leeds UK #982

- Here is a Christmas gift

suggestion for someone who likes tools and has one of

everything. Torq-it Products (www.torq-it.com/products)

(1-888-876-9555) makes a cute 3/8 inch palm ratchet

wrench called the Torq-It Speed Driver. It is about 3

inches in diameter and about one inch thick and has a

pull-rope, like you use to start a lawn mower. You loosen

the bolt or screw with your hand, or a regular ratchet

wrench if it is too stubborn, and pull on the rope once

or twice and the fastener spins off. Is particularly

useful for removing and installing F650 body parts. It

serves the function of a cordless screwdriver or air

ratchet, without the charging or air-compressor, and

takes up much less space in the tool box. It sells for

about $20. My daughter brought me one for my birthday and

I have found it very useful. I recommend it for gadget

and tool lovers. Richard #230.

- These are all replacement

items, but...

- Light bulbs for headlight, tail light, turn signals

- Fuses, definitely

- Flat-tire repair kit (note that adding sealant -- don't

use Slime -- to the tires or tubes helps prevent most

flats)

- Tire valve wrench (small nipple wrench for

removing/tightening/thread-cleaning valve cores --

indispensable for what it does)

- Spare chain (of correct length) and related tools

(chain breaker, etc.), small brush for chain cleaning,

small can of chain lube

- I've found a very small voltmeter (VOM) very handy for

troubleshooting electrical-related problems

- Small white-LED flashlight -- lasts much, much longer

than a regular incandescent flashlight -- I prefer a

headlight type that mounts on a headband, leaving my

hands free

- From my former SAR days I always carry a large survival

whistle (big orange plastic thing, so loud that I have to

plug my ears when I use it)

DesertRider

- Do not forget the compressed

air, either CO2 cartrigdes, or NO2, is you want a laugh

and dispensing unit.

You could be creative, and show off,,,,,, do the

following. Buy a cheapo cig light powered air compressor,

break all of the plastic off of it, shorten the DC power

wire, and air hose. You should be left with a compressor

that fits into your hand(no Lie) that can do a tire in

less than a minute, It starts off the size of a car

batter, and once all the plastic is gone, and and

hose,wire shortened, it can actually be stuffed into a

coat pocket For 11$ at Harbor frieght, if you are

interested in the how to link, i can dig one up off a VFR

mailing list I belong to.. Buy a tire plug and repair kit

from an auto repair store, they are much cheaper than

bike stores, and a tube repair kit from a Mnt Bike shop,

the kind with no separate glue, quicker as well. Maybe

skip the whole chain, and just go with a couple of master

links, and six inches of spare chain for weight savings,

and in a pinch a weapon.Oh yeah, for that low side, some

pain killers to keep you riding until you find someone

who can help. Do not take toooo many, and you will

undoubtedly crash again. devir

- Your best bet before leaving

on a long trip:

1) Fix whatever is broken or questionable. Your chain and

tires should last the whole trip. If the trip will be

longer than new tires, youd best make arrangements before

hand.

2) Evaluate your bikes weak points and bring spares

accordingly. You dont want to leave with a bunch of

things youll never use or can get somewhere on the trip

if you do, or if they do break you can make do without.

3) You did all the scheduled maintainence before you

left.

I try to carry as little as possible and start with a

bike is excellent condition. Not always possible!

echo

- Basically I carry 12 volt air

compressor and a can of fix a flat. You are most likely

to get a flat and FAF has in fact got me the 100 miles to

my cousins house in St Paul with a small rod in my rear

tire. If you have a GS youll need a set of torx bits 3/8

inch drive. I carry a couple of vise grips, a 3/8 inch

drive socket set with unused sockets removed, a service

manual if possible, a roll of duct tape and some

electrical wire (which I fixed a faulty side stand switch

with once). When the ST1100 I own used a little coolant

mysteriously I carried a quart of unmixed coolant. (until

I added a manual fan on switch which when turned on

before entering stop and go traffic solved the coolant

disappearing) You see, basically Im customizing the stuff

carried to the particulkar bike. Which isnt helping you

much! I dont think you can say there is anything that is

goinbg to fail via F650 per se. You can say what might

fail on YOUR motorcycle. I always carry roadside

assistance cards. That and a cell phone which I dont have

would probably insure you of repair. Just grok the bike

and bring what comes to you to bring and go with

confidence! echo

What Tools should I carry on Worldwide

Trips ?

Impossible question to answer

here, because there are so many variables. Have a look at

Werner's book. (See Documentation FAQs).

These are from people who have

been RTW or close.

1 - Spares to Pack for the Big

One

by Werner #547 Ottawa., Werner #547 -- 2000 F650 Classic --

1991 R100 GSPD.

The first prize goes to Flash. Alas, not

everyone is a flush as Flash. I travel light: VISA, MC and lots

of cash. But I'm a sucker for packing tools: only the best:

Snap-On, state of the art, and spare parts. I carry a whole set

of valve adjusting shims (you never know!). I carry a torque

wrench (Snap-On, of course), and a micrometer (guess what make?).

Spare tubes (two each). Oil, water (for the battery), multimeter.

With all that hardware there is no more room left for software

(e.g. clothes). Therefore I look grubby at times. I call it,

"like a macho biker," but others might have a different

opinion. If you're travelling in the so-called third world, it

doesn't really matter. Most of the locals look the same way. The

main thing is to have fun. And that's what it's all about.

There's an amusing incident in "Jupiter's Travels"

relating to spare parts. Ted Simon had carried a spare stator for

his Triumph for quite a while. He never needed it, so he sent it

home to England. The next week his stator went on the blink.

Lesson: Whatever spare part you carry, you'll never need it. What

you'll need is what you don't have.

Carrying spare parts must involve compromises. You can't carry a

spare piston. If you would, the transmission would go. So what is

feasible to take along?

- Plugs and filters (but these are consumables, and don't really count as spares)

- Clutch

cable ( I always

carry one, hence mine never breaks)

- Set of wheel bearings (my rear ones failed after 25,000

miles)

- Rectifier/voltage regulator (it's not heavy, but expensive, and hard to

get at times)

- Brake

pads (again not

heavy)

- Valve adjustment discs (Shims) (2 sizes thinner or

thicker than the ones installed) Important: Know what's

in there. Make a diagram. Be sure that the ones you're

carrying have the thickness printed on them.

- Tube

repair kit and tire pump (a guarantee not to get a flat)

- Light bulbs and fuses (again not heavy)

- A set of good tools, including a torque

wrench and a

multi-meter.

- A repair

manual with

pictures (of utmost importance. If you need a part you

have to get shipped in by FedEX, for example, it's good

to fax a picture to the dealer with whom you have made

prior arrangements in case of emergency)

- A set of credit cards (comes

in handy when you're in civilization, but not very useful

in the middle of the Sahara.

- You can get parts shipped in

within three days to all parts of the world. But be

advised that this is very, very expensive. Customs of the

country you're in usually take at least a third of the

value of the goods imported. The only way to get around

this is if you're a female, pretty, and under 25 years of

age. Believe me, I've tried.

2 - Spares to Pack for the Big One

by Flash 412 (CO)

Never forget that the Classic is Italian.

"For Italian vehicle owners. The first law of Italian parts

is, 'If you have that spare part, you will never need it.' The

second law of Italian parts is, 'If you have the part and need

it, it will turn out to be the wrong part."

- When you change plugs, carry

the old ones as spares until you get new ones. (Don't

forget to get the new ones.)

- YES!

- Change your "lifetime

lubricated" sealed wheel bearings every 24k. 24k is

the "lifetime" of sealed wheel bearings. If

you're going to cross a 24k mark on your trip, maybe

carry the spares. But these bearings are very common all

over the world.

- There are other VR's that

fit. Figuring out which and how, in the middle of

nowhere, can be tricky. Not a bad idea to carry one.

- If you pay attention and

inspect your brakes, you shouldn't need to carry spares.

(But personally, I keep a set of pads for whichever wheel

will need them next under my seat at all times.)

- Put the shims in little bags

or envelopes on which you can write (and re-write) the

size of the contents.

- YES! And maybe a bead

breaker, too. Particularly if you are in the Sahara or

somewhere that is nowhere.

- YES!

- Yes. But... I don't bother

with a torque wrench. BTW... that Doc Allen's Versatool

KICKS A-S-S.

- Hmmm... at LEAST carry a

wiring diagram.

- YES!

- Werner, just HOW do you go

about trying to be female, pretty and under 25?

3 - Spares to Pack for the Big One

by y_kiwi, Lance, #1303, '01 F650GS, '96

G650ST.

From 1-11 I carry 7, 9, 10 (virtually on my laptop) and 11 only.

I have not had to have parts shipped in 4 long trips (Europe,

Europe-Singapore, Australia and Nth/Sth America). A lot of that

is lucky timing - and regular BMW servicing whenever there is a

dealer.

- Can get plugs pretty much

anywhere, washable air filter is the best option (sadly I

don't have one), external fuel filter and spare is a

great bet (BMW fuel filter is expensive)

- Never had a problem...

accelerator cable is another story...

- Never had a problem in 70k

miles on 2 bikes... steering bearings went though.

- Do these fail on their own or

only when hit in a crash? Seems like a part that either

works or doesn't...

- Mine last ones lasted for

35,000 miles and still had a bit left when I replaced

them. I agree with flash.

- I just wait for a dealer...

bit more expensive but...

- Absolutely. some also carry a

spare tube. and tire levers.

- Lamps are easily obtainable

(front light is standard H4 halogen light - I picked one

up at a service station in Argentina)

- Not so sure about the torque

wrench, but multimeter is very useful

- Or have the PDF on your

laptop or a handy website you can FTP from. Repair books

are very heavy

- Cash also works - preferably

us dollars.... :-)

- Or buy from the local BMW

dealer. still expensive but the hourly rates are low so

it evens out. You can also have parts made - especially

in the third world. A frame bolt sheared on my my bike in

Ushuaia and the local moto dealer made a new one from

alloy bolt stock.

I would add:

13: fork seals - they are light and they do

break.

14: duct tape, metal goo, 2 part glue, superglue and wire for

fixing those random bits that break.

15: some also carry chain and sprockets. I don't, but have found

it hard to find sprockets..

and if you are going to send spare parts home send the old part

and install the new one.

Feedback:

- You need to make an

evaluation of the particular bike you are going to take

along. Is it going to be time to do the water pump? How

about the chain and sprockets? My ST1100 suffered from

disappearing coolant for a few years (until I fixed it by

putting in a manual switch for the fan...it got hot but

not overly so in traffic unless you switched on the fan

before hand) so I always brought along a quart of

coolant. How about jumper cables? Don't forget your BMW

road service card. Also, think "what do I need to do

to get this thing to someplace where it can be fixed

right". echo F650GS Dakar, Camden, New Jersey.

What should I pack for Long Trips (Clothes and Spares)

- Bicycle

Shorts (Mike639) Definitely! The best way to keep your

ass from getting saddlesore. There is an added benefit of

some muscular support as well (quads here not your butt

:-). Whether on or off-road I have these on (off-road

ones are different though with hip and thigh protective

pads). A very inexpensive way to improve the enjoyment

from your long distance riding.

- One pair of

jeans, and more (BestRest). If you're going to bring

jeans, one pair will do it. Personally I've found jeans

to be less useful when motorcycle touring. I've switched

to wearing ExOfficio clothing or certain things from REI

or NorthFace. I'm very particular about what I bring with

me and it's got to have certain properties like being

lightweight or having some technical benefit such as sun

protection/cooling or the same garment type in short/long

sleeves. Anyways, I experimented and how have the

collection that suits me well for just about any trip. As

far as the off-bike gear goes I layer. I have REI fleece

jacket and pants (but the special version which is

thinner and lighter weight) and layer a Gore-Tex

windbreaker/pants over this in case the camping is wet. I

have off-bike gloves/combo to match so it's easy to think

about what to wear when off the bike. Cold weather,

fleece, really cold fleece and Gore-Tex overprotection,

city stuff ExOfficio/REI pants/shorts with whatever shirt

of the moment. No cotton t-shirts here as I prefer the

active wear stuff from Nike, NorthFace and REI. It lasts

longer when actually being used, packs lighter, and dries

faster. Ditto on the ability to buy stuff and for sending

stuff home

- Using the

post office (Alan 442). If you've got to bring a lot of

medicine with you this might take up a lot of room that

you could do better with over time. Remember it's a

battle of time vs. space. Send things to you and get them

via poste restante or friends. Alan also caught that you

have too many socks. I had three pair for the entire

three weeks of the Dakar. Remember with a rest stop you

can always find a Laundromat, either a drop-off wash and

fold or a do it yourself place. Even when you're die-hard

ride all day, sometimes a nice stop can be made for you

to eat and do your clothes.

- Werner's

comments. Werner and I think alike in that there is no

substitute for being able to fix your bike by yourself. I

"reserve" the left pannier for this for my

trips (mostly off-road backcountry affairs), spare tubes,

oil filter (for my other bikes not for the F650GS as I

run the Scott's reusable one), air filter oil (I run the

K&N), and other stuff like Werner has. But all of

this has to be balanced as Flash said against your

ability to make said repair (why carry two sets of tubes for

each tire if you don't even know how to take the wheel

off of the bike).

- Of you're in

the US/Canada most of the times help is just a phone call

away. Something like membership in BMWMOA so that you can

get the "anonymous" book goes a long way and

IMHO is better than BMW's "roadside dis-assistance"

program.,

- Shank's words

of wisdom. Definitely do what he says. Lay it all out.

Weigh it (at least I did to make a spreadsheet), then

pack it, unpack it, pack it again, then take a local

trip, camp out somewhere close and pack and unpack in the

dark. You'll quickly see how much time it takes the more

stuff you have. As far as the cooking while riding goes,

I can't vouch for this. I prefer to eat first then ride.

but then again YMMV.

My comments:

1. Draggin' jeans are too bulky: Get rid of these, stick

to touring motorcycle wear, and think about not having

jeans at all, if you must one pair only.

2. Fewer socks and underwear: Bulky and easy to buy on

the road (and one of life's small pleasures).

3. 1 set of real clothes, Pants last longer than shirts

and can be worn twice.

4. Maps - take it easy, carry those you need now and send

the rest ahead or stop at AAA and get them as you go

along.

5. A camelback - this is the one thing that I constantly

remind people of. You need to CONSTANTLY hydrate. So

drinking (water) while riding is what you need to do. If

you "feel" thirsty" it's too late. If you

get this in a small backpack version you've also got a

place to put some food and personal accessories.

- Werner

#547: Spares to Pack for the Big One:

There's an amusing incident in "Jupiter's

Travels" relating to spare parts. Ted Simon had

carried a spare stator for his Triumph for quite a while.

He never needed it, so he sent it home to England. The

next week his stator went on the blink. Lesson: Whatever

spare part you carry, you'll never need it. What you'll

need is what you don't have.

Carrying spare parts must involve compromises. You can't

carry a spare piston. If you would, the transmission

would go. So what is feasible to take along?

(1) Plugs and filters (but these are consumables, and

don't really count as spares)

(2) Clutch cable ( I always carry one, hence mine never

breaks)

(3) set of wheel bearings (my rear ones failed after

25,000 miles)

(4) rectifier/voltage regulator (it's not heavy, but

expensive, and hard to get at times)

(5) brake pads (again not heavy)

(6) valve adjustment discs (2 sizes thinner or thicker

than the ones installed)

Important: Know what's in there. Make a diagram. Be sure

that the ones you're carrying have the thickness printed

on them.

(7) Tube repair kit and tire pump (a guarantee not to get

a flat)

(8) Light bulbs and fuses (again not heavy)

(9) A set of good tools, including a torque wrench and a

multi-meter.

(10) A repair manual with pictures (of utmost importance.

If you need a part you have to get shipped in by FedEX,

for example, it's good to fax a picture to the dealer

with whom you have made prior arrangements in case of

emergency)

(11) A set of credit cards (comes in handy when you're in

civilization, but not very useful in the middle of the

Sahara.

(12) You can get parts shipped in within three days to

all parts of the world. But be advised that this is very,

very expensive. Customs of the country you're in usually

take at least a third of the value of the goods imported.

The only way to get around this is if you're a female,

pretty, and under 25 years of age. Believe me, I've

tried.

Preparation for the Big One: Bike: 2000 F650

(actually 1999) Classic. Lowering kit, heated had grips,

BMW alarm, BMW crash bars, Aprilia hand protectors,

Triumph fork protectors, Staintune exhaust system,

15-tooth front sprocket, Acerbis 27-litre tank, Touratech

skid plate, Jesse radiator guard, Jesse luggage carriers

and aluminum side cases, Hepco and Becker plastic top

case, Corbin saddle, Fenda Extenda, Scottoiler, in-line

fuel filter, Hyperlites; tires: stock Silverstone

Trailwings. The Big One: London- Cape Town -London,

35,650 km in five months and six days, over the choicest

parcels of real estate Africa can throw at you. Of course

some of you want to know how this well-prepared

wunderbike with its less well-prepared rider made out. I

would like to tell you. Fortunately a book about this

trip just came out, written by some guy named Werner

Africanus, whom I know intimately. However, the

constitution prevents me from blowing this guy's horn, or

- Allah forbid - flogging the book. Should your curiosity

get the better of you, you could contact me at the

address below. bauswe@yahoo.comBottom Line for

the Big One: If you want to do adventure touring in a

relatively big way, you need three things: (1) A reliable

bike; (2) A bit of money; (3) Lots of time.

To (1): We all have the first requirement. Any kind of

F650 is fully capable of doing a Big One. Forget larger

bikes. You don't need all that power, and if you ever get

stuck in mud, you can forget to get going again. R1150's

are the SUV's of motorcycles. Good on the Interstate. But

would you ever dare to take it into the mud?

(2) Money. You cannot take along enough of it: Cards,

cash, T.C.'s. For example, before you get going you have

to get a Carnet de passage en Duane, available through

the Canadian Automobile Association. This is a customs

document which will guarantee to the country you are

visiting that you will export the bike, or else forfeit a

certain amount of money. Iran, for example, requires a

deposit of 110% of the value of the vehicle. For my 2000

F650 I had to leave a deposit of US$8,000 with the CAA.

Of course I will get it back when the bike is signed in

again for Canada. My visas cost me a cool US$500, and I

have to get several more on the road. And there are more

bills to come. Adventure motorbiking is by no means a

poor man's sport. My trip around Africa (five months and

six days) cost me an estimated US$17,000.

(3) Time, a rare commodity for most of us, unless we are

retired, like this old geezer (now 65). So age is a plus,

provided you are still healthy. You must live with this

in mind. "Use it, or lose it." This goes for

all body parts. If you have all of the three

prerequisites, you are ready for the Big One. "Just

do it!" Werner #547 Ottawa

- Flash 412

(CO): Never forget that the Classic is Italian.

"For Italian vehicle owners. The first law of

Italian parts is, 'If you have that spare part, you will

never need it.' The second law of Italian parts is, 'If

you have the part and need it, it will turn out to be the

wrong part.'"

1. When you change plugs, carry the old ones as spares

until you get new ones. (Don't forget to get the new

ones.)

2. YES!

3. Change your "lifetime lubricated" sealed

wheel bearings every 24k. 24k is the "lifetime"

of sealed wheel bearings. If you're going to cross a 24k

mark on your trip, mebbe carry the spares. But these

bearings are very common all over the world.

4. There are other VRs that fit. Figuring out which and

how, in the middle of nowhere, can be tricky. Not a bad

idea to carry one.

5. If you pay attention and inspect your brakes, you

shouldn't need to carry spares. (But personally, I keep a

set of pads for whichever wheel will need them next under

my seat at all times.)

6. Put the shims in little bags or envelopes on which you

can write (and re-write) the size of the contents.

7. YES! And maybe a bead breaker, too. Particularly if

you are in the Sahara or somewhere that is nowhere.

8. YES!

9. Yes. But... I don't bother with a torque wrench.

BTW... that Doc Allen's Versatool KICKS A-S-S.

10. Hmmm... at LEAST carry a wiring diagram.

11. YES!

12. Werner, just HOW do you go about trying to be female,

pretty and under 25?

- y_kiwi: From

1-11 I carry 7, 9, 10 (virtually on my laptop) and 11

only. I have not had to have parts shipped in 4 long

trips (Europe, Europe Singapore, Australia and nth/sth

America). A lot of that is lucky timing - and regular BMW

servicing whenever there is a dealer..

1: Can get plugs pretty much anywhere. Washable air

filter is the best option (sadly I don't have one).

External fuel filter and spare is a great bet (BMW fuel

filter is expensive)

2: Never had a problem... accelerator cable is another

story.

3: Never had a problem in 70k miles on 2 bikes...

steering bearings went though.

4: Do these fail on their own or only when hit in a

crash? Seems like a part that either works or doesn't...

5: Mine last ones lasted for 35,000 miles and still had a

bit left when I replaced them. I agree with flash.

6: I just wait for a dealer... bit more expensive but...

7: Absolutely. some also carry a spare tube. and tire

levers.

8: Lamps are easily obtainable (front light is standard

H4 halogen light - I picked one up at a service station

in Argentina)

9: Not so sure about the torque wrench, but multimeter is

very useful

10: Or have the PDF on your laptop or a handy website you

can FTP from. repair books are very heavy

11: Cash also works - preferably us dollars.... :-)

12: Or buy from the local BMW dealer. still expensive but

the hourly rates are low so it evens out. You can also

have parts made - especially in the third world. A frame

bolt sheared on my my bike in Ushuaia and the local moto

dealer made a new one from alloy bolt stock.

I would add:

13: Fork seals - they are light and they do break.

14: Duct tape, metal goo, 2 part glue, superglue and wire

for fixing those random bits that break.

15: Some also carry chain and sprockets. I don't, but

have found it hard to find sprockets.. and if you are

going to send spare parts home send the old part and

install the new one....#1303 F650GS 2001, G650ST 1996

- Bernard: Packing

Tips and Techniques. www.helen2wheels.com is a brilliant

site that explains how (and why) to pack a bike - with

the emphasis on using a large duffel bag (or two) where

the top box normally goes. The site features clear

photographs and detailed instructions - well worth a

visit. In addition, Helen also has some great kit on

offer for those a that may need it. I met a European

couple (Tjeert and Ingeborg from Holland and Germany) on

a recent mini-tour and they use a very similar system,

which makes a lot of sense to me. It may not apply to all

tourers, but it should prove insightful to some. Please

excuse me if all are familiar with this nugget of info! Cheers,

Bernard Cape Town, South Africa.

- Spakur: First

thing is to fix whatever may be wrong with the bike. This

you have done. Second is to think about any areas which

have given trouble in the past and bring relevant

parts/tools to fix them. Third is to go over the bike

completely checking tightness of bolts, condition of all

hoses (there are a lot of them of the F650), shocks,

forks, cables, spokes, wiring, brake pads. Everything you

can think of. It sounds like you've done this too. I

think you you have brought a good selection of spare

parts. You didn't mention dealing with flat tires, so I'm

assuming you've got spare inner tubes and patches, the

means to get the tires on and off, a way to inflate the

tire (electric pump is best...or a foot pump) and a can

of fix-a-flat. The BMW book of dealers locations and

phone numbers and other places/sources of parts would be

helpful, as would the list of people willing to help BMW

riders from the IBMWR website. (if any in that neck of

the woods) If you have just changed the rear sprocket

bearing etc I don't think you need a spare. Also, wheel

bearings inspected to be in good condition should be fine

for the trip. I don't think you will need valve shims if

you have just inspected them. As I recall you have a

number of miles on your bike and it is a few years old.

So you must be prepared to deal with something unexpected

breaking. Unfortunately it isn't possible to carry

something to fix everything! That is why connections to

places of repair/sources of parts/ people who will help

is important. This is the best advice I can give you.

That and if something should require time to repair, my

advice is to accept the delay as part of the

trip/adventure. In my experience when that happens I will

meet some interesting people and have maybe the most

interesting experience of the trip. Good luck and have a

safe trip!. Just to try and be helpful to those planning

a trip and wondering what to bring in the way of spare

parts. Its a good idea to eliminate bringing things which