Misc. Braking Questions FAQ

compiled & edited by Kristian #562

Please read the Disclaimer before attempting any work in this FAQ.

Problems & Solutions

Aftermarket

Brake Parts

Misc. Brake Questions

Other (Separate) Brake FAQs:

Bad master cylinder, caliper or brake

fluid?

Problem: I recently bought

a 2000 F650 and after about 50 miles, the front brake lever went

all the way to the bar. I could pump it up, but after that first

occurrence, it frequently, but not always, went to the bar. Took

it back to the dealer and they said the master cylinder needs

replacing (after the technician originally thought they were OK,

because of the intermittent problem). While waiting for the part,

I read the brake FAQ and decided to change the fluid in both

front and rear brakes, as the brake fluid was the color of coffee

... actually more like espresso!. Now, I've ridden the bike about

10 miles and the brakes seem nice and tight. Is it possible that

I really do have a bad master cylinder, or could changing the

brake fluid fixed the problem? Also, if the brake lever goes to

the bar, how would one know if it's a bad master or front

caliper?

Solution: Well, after

changing the "espresso" brake fluid to "gin"

color, I went out and practiced panic stops from 25 to 45 mph,

and brakes are still working fine, so I'm inclined to think it

was bad fluid and not a bad master cylinder. Phoenixtoohot

Feedback:

- It sounds to me like you had

a lot of air in your fluid. My fluid looked just like

that the first time I changed it, less than a year after

the bike was assembled by the Italians. Maybe they were

using espresso. If it was me, I would change out the

fluid once more, just to be sure that you got all of the

expresso out of the lines. A careful bleed of the brakes

will easily get all of the air out of the lines and if

the brakes feel fine then, that was your problem and I

would worry about the competence of your mechanic. In my

limited experience, a bad master cylinder will cause the

brake lever to slowly come back to the grip over a period

of time, not come back immediately - that indicates air

in the line. Richard #230: 1997 Funduro

- "Even bad brake fluid

wouldn't let the lever come all that way in"

BZZZzzzttT! A few small air bubbles in the brake fluid

sure will allow the lever to come to the bar. Brake fluid

absorbs water from the atmosphere. Brake fluid can reach

temperatures higher than the boiling point of water.

Steam/water vapor bubbles are more or less the same as

air bubbles once they form in your brake line.

- "Even bad brake fluid

wouldn't let the lever come all that way in" Not

true. Had this problem with rear brake after braking a

lot. Changed the fluid, solved the problem... If your

problem happens after some braking, than I would go for

the fluid. gim '97 F650, Waltham, MA.

- I once used brake fluid from

a tightly closed container that had only been opened once

before, some 2-3 months earlier. Soon after, on a trip

with some "inspired" riding I suddenly lost the

rear brakes, due to vapor lock. When I had the brake

fluid checked (I really did not think it could be the

fluid, but found no other cause) we found a too high

water content. Brake fluid is highly hygroscopic (Absorbs

water). haakon#626 (Norway,12-1999- F650GS).

Rear

Brake Failure?

Change your

Fluid REGULARLY! Check your Brake Hoses!

Feedback:

- Coming back from Santa Cruz

today when, after a lot of breaking on rt 9 (beautiful

ride with lots of curves in the woods), the pedal went

all the way down with no braking at all. It happened

progressively, but fast. After the third time after I

felt the pedal somewhat different, there was no more

braking action. I thought the brake line broke, leaking

fluid. NOPE. It was just the temperature. After waiting

for half an hour (adjusted chain tension in the meanwhile),

the bike was fully back to normal. Is it possible the

problem was caused by the fluid ? I believe that it

hasn't been changed for a long time (never by me at least

:( )...I plan to bleed the brakes anyway, but it would be

nice to know if this problem can be caused by old fluid.

If this is not the case, then I have to try to brake less

the next time :) gim (orange '97ST)

- Brake fluid is hygroscopic,

it absorbs water from the air. This is one reason you are

supposed to change it annually. Water lowers the boiling

point of brake fluid. When it boils, there are gas

bubbles in the lines. These compress when you apply lever

instead of moving the pads. When it cools, they go away.

Don't use your brakes so much. And change your brake

fluid. Flash #412 (CO)

- Had the same problem.... the

fluid in the stock bike sux. Flush the system had new Dot4

put in ....never had problem again. scx

Brake

Mount Failures?

Only ever heard of ONE instance. ed.

Instance 1

OK, right to the point here. I have just had the sh*t

scared out of me by a brake mount failure that caused a total

loss of the front brakes at speed on my 98 F650ST. I went to

brake at 30-40mph and there was a CRACK followed by the clunk of

my entire front brake caliper assembly rotating out of place on

its remaining mounting bolt resulting in no brakes and a floppy

brake lever. On examination the lower of the two caliper mounts (where

the caliper is bolted to the fork leg) had fractured vertically

through the bolt hole, leaving the caliper hanging on via the

upper mount and the break pads totally dislodged and hanging

loose.

Q1. Has anyone heard of it happening before?

Q2. Is this a known issue?

Q3. Is this something that BMW should know about?

Q4. Is this a weld repair or a new lower fork job?

I would advise anyone to take a close look at the

brake mountings on the forks and check for cracks just in case.

This was really sudden and with no warning. Had it happened at

motorway speeds I would not be here to make this post. I have

just had all the covers off this and taken a look in the cold

light of day. The good news appears to be that the mountings to

the fork leg are ok. The bad news is that it is the caliper

mounting plate that has failed. This plate connects the caliper

to the forks and mounts two pins that allow the caliper to move.

The mounting for the lower of these pins has fractured vertically.

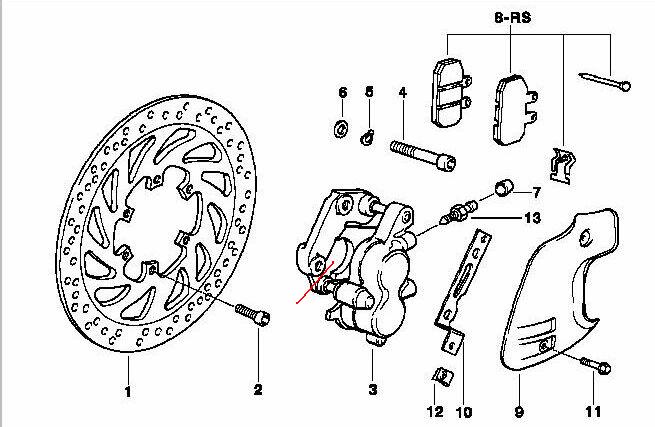

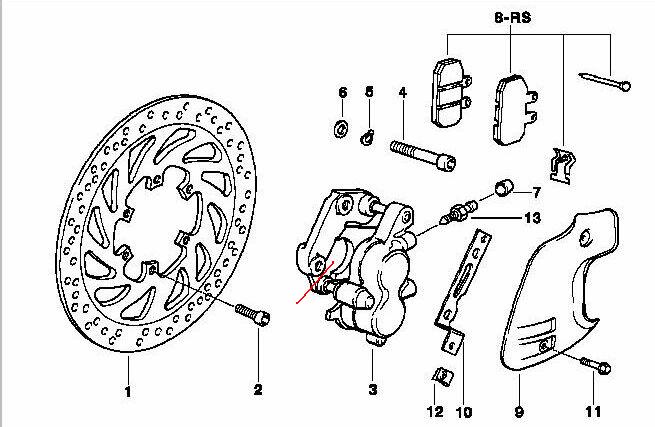

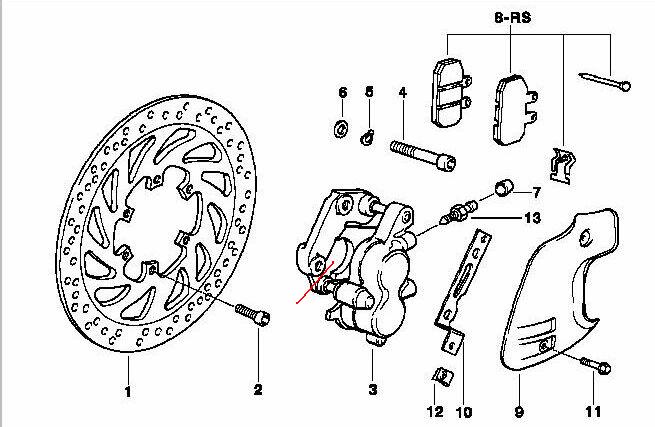

You can see a diagram above of the brake assembly. The mounting

that has fractured is just below the lower of the two bolt holes

on fig. 3 (see above). As you can imagine, my BMW dealer is

taking a real interest in this and will be looking at this ASAP

with a view to kicking it up the BMW ladder if there is no sign

of external forces at work. MrWolf, Dave-O'C-98 F650 ST

- <Q1. Has anyone heard

of it happening before?> Not that I know of.

<Q2. Is this a known issue?> Obviously not.

<Q3. Is this something that BMW should know

about?> Absolutely. Based on the history of the

bike, I would possibly involve a lawyer as well. Who has

maintained the bike? BMW Factory service? You personally?

A previous owner who's work no one can verify? If I had

to venture a guess, I would suspect someone has radically

overtightened that bolt, although I'm not completely

ruling out that a completely normal outer fork tube

torqued to the proper specs would break.

<Q4. Is this a weld repair or a new lower fork

job?> Given your experience, would you ever really

trust a repaired bit? I would work on a replacement,

preferably on BMWs dime. David #476, '99 F650.

- I would not use welding as an

option for this repair given the importance and the

nature of it. Will in CA

- I'd love to have a look at

that fracture. My guess is that you'll find an inclusion

(looks like a chunk of slag). Marty #436-Chicago-97 F650F

Leaking

Brake Line?

- I posted an earlier message

this past Tuesday (24-Sep) about a possible rear brake

line that was leaking. Well just for the hell of it I

bled the rear brake line as per FAQ (many thanks to the

contributors). After the job was completed I found that I

had drops of liquid under the bike. Shining the light

between the rear wheel and the engine while depressing

the brake pedal quickly illustrated that there was indeed

a leaking brake line. In front of the rear wheel and

behind the transmission the rear brake line has some

fittings to join two separate pieces of brake line. It is

the fitting that is leaking. So off to the dealer for a

warranty repair for a 2001 F650GS with 14500km (9000

miles). Perhaps first I will try to see if I can tighten,

if it is lose, the fitting. Though it looks very crowded

at the fitting. Rodger#1046

- Took the MC to the dealer

this morning. Dealer has concurred that the rear brake

line is leaking. The whole brake line will be replaced

under warranty. The parts were ordered today (Monday) and

could arrive within a couple of days. Rodger Lucas (#1046)

2001 F650GS 14500 km (non ABS).

- Next.

Leaking Front Master Cylinder?

If it leaks, it will quickly corrode metal parts,

including allows and strip paint. Clean it up quickly and fix it!

Causes:

- Reservoir Overfilled.

Solution. Take out some Fluid with a CLEAN Turkey Baster

or Better yet, BLEED some fluid out.

- Seal Problem #1: There

is a bit of rubber, from one of the punched holes on the

diaphragm, that is still attached, but on the inside, so

you can't see it. It raises the lip of the seal enough to

cause leaking. btw, CHECK for splits or defects in the

sealing lip of the Diaphragm first. If there is a defect,

that's where it's weeping from, and you will need a new

diaphragm. No amount of sanding of the lid will help you

if the Diaphragm is split or has an extrusion (manufacturing)

defect.

Solution.

Undo Screws, Check Diaphragm, Reinstall. Do NOT

Overtighten the Screws. If the Seal is good, it will seal

just fine. One

thing you should always do is to coat the threads of the

master cylinder lid screws with anti-seize compound. If

there are any screws that are going to corrode on your

bike it is going to be these screws. (Richard #230). If all else

fails, replace the diaphragm and make sure that the vent

grooves in the top of the master cylinder cover are clean.

- Seal Problem #2:

Rubber diaphragm under the lid was not re-installed or

tightened (most likely too tight) correctly, or if

there is a problem with the vent holes under the cap.

Solution.

Undo Screws, Check Diaphragm, Reinstall. Do NOT

Overtighten the Screws. If the Seal is good, it will seal

just fine. If all else fails, replace the diaphragm and

make sure that the vent grooves in the top of the master

cylinder cover are clean.

Feedback:

- Brake oil container overflow

Hi! I had a short ride around town last night along w/ my

buddy. I rode a 2002 F650GS (non ABS) while my friend

brought an F650CS w/ ABS (my old bike). After stopping

for a short break, I noticed that both our brake oil

reservoir (on the right side of the handlebar) had some

oil stains. Probably from an overflow. I'm going to have

both of our bikes checked tomorrow and I hope the

mechanic can solve our problem. Our bikes are still new

and we've run only about 500kms each. I got both bikes

from the same bike dealer. Just curious, can there be any

other reason for the oil overflow aside from maybe the

bike dealer put too much brake oil? Has anyone have this

same situation? Jagged.

- I have a problem with brake

fluid weeping out of the front master cylinder. (this is

for an '03 CS w/ 7k). Within a couple weeks of having the

bike, someone pointed out that fluid was weeping out, and

claimed the dealer must have overfilled the reservoir.

This was ~1500 miles. I flushed the fluid for both front

and rear cylinders, and I haven't had any more weeping

until now. I've put about 1500 miles on the bike since

early march, but the weeping didn't start until yesterday.

Just a drip yesterday, but several drips today. The only

thing I can think of is temperature - it warmed up nicely

today. But why didn't I have any weeping last season? I

changed the fluid at the height of the summer heat. If

anything, shouldn't I need to top the fluid up due to

brake pad wear? I can remove some fluid easily but I want

to make sure I'm not experiencing an underlying problem.

(It is leaking From the weep holes. I think it might also

be leaking from the front of the cover seal, but I'm not

certain that wetness also originated from the weep holes.

Since it's coming out the weep holes, I thought it was a

fluid-level problem. Thing is it's weeping out the weep

holes, so do I really have a leak problem? If there was a

problem with the seal I'd expect fluid to leak somewhere

else). Thanks for the tips! wicked94pgt BBG#22 F650CS,

Natick, MA

- My GS wept from Day 1.

Problem? There was a bit of rubber, from one of the

punched holes on the diaphragm, that was still attached,

but on the inside, so you couldn't see it. It raised the

lip of the seal enough to cause leaking. Solution 1. Pull

the diaphragm out of the cap unit and check it thoroughly.

Solution 2. I also got some VERY fine wet and dry and

sanded a smidgen off the outer edge of the cover (after

removing the rubber diaphragm), so that I was sure the

lid wasn't engaging the reservoir top before the seal

could seal properly. If you do that, do just a VERY small

amount and CLEAN CLEAN CLEAN CLEAN it of all filings

before replacement. btw, CHECK for splits or defects in

the sealing lip of the Diaphragm first. If there is a

defect, that's where it's weeping from, and you will need

a new diaphragm. No amount of sanding of the lid will

help you if the Diaphragm is split or has an extrusion (manufacturing)

defect. (Is rubber extruded?). Kristian#562

Front

Master Cylinder Rebuild?

Q. The front brake plunger on my '94 Classic

F is sticking. Does this mean that it is shot and really should

be replaced or can it be stripped and greased up. I saw on the

Motobins website that they only supply the master cylinder and

throttle assembly as one unit. Is this correct? Pat#1210

According to the GS Manual this item should be

replaced (Front/Rear Master Cylinder Cup) every 40,000kms

for Bikes WITH ABS. This Boot can be replaced.

The BMW part #'s:

- The Classic Part No. for

the Boot is Unknown.

- The GS Repair Kit Front

Master Cylinder (What is IN it is unknown) is 32 72 7 655

396

- The GS Repair Kit Rear

Master Cylinder (What is IN it is unknown) is ALSO 32 72

7 655 396. (So it looks like the Piston is the SAME for

Both F/R).

- Chances are the Classic

uses the same as the GS and that SOME other bike uses a

Similar Piston. Anyone?

Feedback

- Theoretically the master

cylinder and caliper can be rebuilt. I tried to buy a

rebuild kit for a leaky BMW master cylinder and was told

that they don't sell master cylinder rebuild kits, I

would have to buy a new master cylinder for some

astronomical sum. That was a different BMW than my '99

Classic. So, I'd imagine that there is a rebuild kit for

the master cylinder but that no dealer outside of BMWAG

has one in stock and they can't be shipped overseas for

national security reasons. I think your front brake

caliper probably just needs to be cleaned. Shank NYC USA

What about Sticky Pistons/Dragging or

"Binding" Brakes

by Andy #982,

Mark #403 & Kristian #562

Severity: It can be dangerous, so fix

it soon! Here are some examples:

- Rear brake catches fire.

First I sign is when I went to change gear and the bike

starting slowing at rapid rate. BMW surging I thought.

About 5 miles later I stopped at the traffic lights and

motorist behind start waving at me, this when I

discovered that rear brake assembly was on fire, not far

from the fuel tank under the seat. Bloody quick dismount

from bike and called the fire department. Five minutes

late two fire engines arrived! Communications problem?

Only real damage seems to be the rear brake assembly and

speedo sensor. The bike has only done 14,000 on mixture

of dirt and highway (no speed limits in my home state of

NT). Has any one had problems of rear brake overheating?

I was only doing about 125 KPH at the time of the problem.

Iain

- I've had problems with the

rear brake sticking, thus causing overheating, but

thankfully not as serious as what you experienced. It can

get pretty hot real quick. Oyvind #1052, Norway

- No fire, but really hot.

Having the rear brake adjusted with too little slack will

do this. You get the brakes hot, the fluid expands a

little and the pads are always touching, which makes the

fluid hotter, which makes the pads push harder on the

disk. Pete

Generally:

- The brakes drag (slightly) to

stop anything getting between the pad and disk that might

cause scoring. Its simpler for the OEM than fitting any

other sort of protection to the pad/disk.

- If the wheel spins freely for

maybe 10 seconds (or less, even a 3-4 good rotations)

after a good shove, all is OK despite some slight rubbing

(not squealing) noise.

- If it is dragging, in other

words it gets hot to touch even if you do NOT use the

brake, check the fluid level before anything else and see

if removing some helps. Stay within the sight glass

limits, but you'll find half full to low may be better

than full.

- If you've played around with

your forks/axle lately, you may have put the bike

together with a slightly different wheel position.

There's a surprising amount of variation in how the forks

will come to rest with everything loosened up, and how

they will end up when you tighten the triple clamps, axle

pinch bolts and fork brace. If you tighten things up with

a slightly different angle than you had previously, you

can get additional brake drag until the pads "seat"

themselves again to the new position. See the Front Wheel Removal FAQ for tips on how to put the forks

back properly and the Rear Wheel Removal FAQ for the rear.

- For the Rear Check the Brake Plunger moves freely. For the Classic,

Undo the The Allen Key Screw (i.e. the Brake Pedal Bolt). Take

it off the Axle and Grease the Axle, and the Plunger and

connections. Put some Vaseline or Grease in the rubber

boot.

- Next check Check the Rotor is

not Warped. They warp easily if they get too heat for too

long or they are dropped when you do a wheel change or

any maintenance work e.g. Bearings. Here are some New Rotor sources.

- Next idea is to replace the fluid and bleed. Old fluid with water in it can

expand under heat before it all goes spongy.

- Next idea is to check the

Pistons are CLEAN. What often happens is that as the pads

wear the pistons extend further and further out of the

caliper until you change the pads. Then with new pads you

push 'em back in again. But if you didn't clean the

piston's at all, all that gunge ends up going back into

the seal and can cause the piston's to "stick"

somewhat.

- Don't forget to ALSO check

whether or not the master piston returns completely!

- After that its strip down and

new seal time at which point you'll want to check the FAQ

or maybe see a mechanic. If a seal kit is available, just

get a clean place to work and replace every seal in the

kit. Clean everything as you go, you are looking in

particular for anything that might prevent fluid getting

back to the master cylinder. Lift the rear wheel up an

check if the brakes are slightly on even if you're not

breaking. If they are, this often causes over heating and

you have to overhaul your brakes, which isn't very hard.

If you find any inside dirt coating the brake cylinder or

piston then polish it away using a light rubbing but

never polish in and out, go around and around or you may

cause leakage through micro scratches. Then use new

gaskets/o-rings.

Feedback/Suggestions:

- Sticky M/C piston sounds very

strange. Brembo makes a special piston Vaseline for that.

I'd buy a rebuild kit, pop the old piston out (hammer and

ten penny nail are all the tools you'll need), lube up

the new one, slather the seals and pop that in (hammer

and 11mm socket (or close enough) are the tools you'll

need). I still say that if you are getting drag on the

front brake, you have mung and debris on your caliper

pistons preventing them from seating all the way. Take

out the pads, pump the lever a couple of times to get the

pistons to stick out a little more than usual. Spray

profusely with brake cleaner, get out of there before the

fumes go to your head, when the fumes clear, open bleed

valve (or take the top off the M/C reservoir) and cram (and

I mean CRAM!) the pistons all the way into their bores,

use a C-clamp if you have to (I've done it in the past),

then put in the new pads, make sure the reflex pins are

pushed all the way into their bores as well (and make

sure the reflex pins are substantially greased up and not

sticking in their bores). Don't forget to to put a lil'

grease or Auntie Seize on the backs of the pads to

curtail squealing. And THEN, if you still have a bit of

brake drag, go for a ride. I put on stainless lines and

new Galfer pads this weekend, I had some front brake drag

initially but after bedding in the pads a la Method du

L'iclair (Flash), no more front brake drag. Shank

- Further to my recent postings

about my front brakes (sticking plunger binding discs etc)

I have the following update: After replacing the pads (the

old discs still had life left in them) and bleeding that

God 'awful brown gritty stuff from the lines and

replacing it with nice clear brake fluid my pads were

binding on the discs. I took the whole thing apart again

but to no avail. Fearing the worst for my master cylinder

and calipers I took it to the shop. They stripped them

down as best they could, cleaned the caliper pistons

copaslipped the back of the pads and again bled the

system. This still didn't fix it, so last night I put the

old pads back in and lo and behold problem gone. One of

my colleagues at work ('91 K100) suggested that the

pistons had corroded on the outside (the bike had been

laid up for some time before I bought it) so since the

new pads meant pushing the pistons home they simply

jammed in the bore. Logical? Pat #1210.

- Logical? Possibly. But

sticking pistons is what I suggested upon your first post.

And I still stand by that statement. Take the pistons

out, ScotchBrite' em real good and (please read carefully)

lube the slide pins of the caliper, these can also

contribute to sticky brakes when new pads are put in. Ok,

so replacing the new pads with old has temporarily fixed

the problem. What are ya gonna do when the old pads have

no more meat left on'em? Shank.

- Bound rear brake. After

removing my rear wheel (Classic '97) and replacing it. I

checked the brake whilst on the centre stand by pressing

it down checking it had come on and then checking that it

had released. Riding to work this morning all went to pot

:( After using the break a few times it started to bind.

it just is not releasing, luckily I only had 500m to go

after they bound (was really lucky with the lights) and

was able to go really slow after that. There was no

pressing the pedal when the wheel was off. That is a

silly thing to do. All I did was the wheel off, change

tyre, wheel on procedure that I have done loads of times

before. Normally it is all hunky dory. Even this time,

the wheel went on first attempt. It is straight, that was

checked and rechecked. I know I can release the brake at

the pedal end with the bolts. But is this just going to

mask a problem or is it the correct fix? So, my bike is

outside work, the rear break is pretty much locked,

questions are: 1, What do I do to unlock it? 2, Why did

it happen?.

- What xls said, check you

didn't lose the L or R Spacers when you put the wheel

back on AND check the brake caliper mount on the swingarm

is nice and loose but in position on that little lug

before you go tightening up the main axle nut. Good point

Chris, James I put a dab of Copaslip (a sort of copper

impregnated "dry" grease on those pins to help

it along. (Don't get near PADS.!). Try that first, then

remove the wheel and recheck. Check Alignment at same

time, sometimes goes on skew when torquing main nut,

unless you have third hand to push k.

- Make sure the pads are not

stuck on the retaining pins as well. You should be able

to move them slightly independent of the pins. I also

just thought that if your rotors are worn and the pads

are supposed to fit between the lips at each edge perhaps

a pad is riding on a lip. The goal should be to have the

pads riding on the pins and against the rotor in the same

way as before you pulled the wheel. Chris in Santa Cruz,

CA #782 - 30-Jul-02

- Bound rear brake - Answer.

Ok, I have found the cause. After checking the wheel/axel

end all seemed OK. I went to the brake pedal end,

detached the brake pedal from the brake plunger and moved

it up and down. It was sticking, definitely not rising by

itself. So, I worked the pedal up and down a little, It

is now not perfect but it is better. A clean / grease up

of the area is in order. : J@mes NZ #848.

- *Sigh* We've gone over this

before, I'm SURE it's in the FAQ somewhere, but for those

of you city folks just too damn busy to read the FAQ,

read on and, please, if you would be so very kind........BLOODY

PAY ATTENTION!!!

- Take the pads out.

- Remove the caliper from the

fork slider.

- Pump the brake lever to get

the pistons out far enough to see a clean spot on them,

BUT NOT TOO FAR!

- Spray profusely with brake

cleaner, use two cans if you have to.

- Take whatever brake fluid

remains in the reservoir out, use a turkey baster, eye

dropper...whatever or simply use the Flash method and

turn the bike over to get it out.

- CRAM the pistons ALLLLLLLL

the way into their bores. (now here's the REALLY

important part, please pay attention)

- Remove the piston assembly

from the back assembly. Yes, they do come apart.

- Go ahead, give a good try,

they'll come apart. Nope, you won't break anything.

- Clean the mung, bung and

grunge off the slide pins. Grease them profusely. Use

lots of grease. No, MORE than that. That's it, grease it

up good. While you're at it, fill the lil' rubber booty

thingies with grease.

- Now put the slide pins back

into their lil' rubber booty thingies. Yes, cram'em in

there. No, you're not going to break anything Yes, you

are putting the caliper back together.

- CRAM those slide pins in

there. So what if some grease comes out, wipe it off. No,

you aren't going to hurt anything. Sheesh. REALLY cram'em

in there. Ok, pull'em out a bit, make sure there's some

resistance. Now cram'em back in there really good. NO,

REALLY cram them in there. Keep cramming. I don't think

they're all the way in yet. (Don't ya just hate it when

ya hear that?)

- Ok, when you see the lil' hat

part of the lil' rubber booty thingies pulsing with each

cram, they might be close to being all the way in there.

- Try squeezing the lil' hat

part to poot out the rest of the air trapped in there.

Now cram'em in some more. Oh come on, put some

testosteronized muscle into it, CRAM'EM!! Sheesh, how can

someone so limp-wristed ride a bike? I said, CRAM'EM IN

THERE LIKE A MAN, DAMMIT!!!! Very nice, now stop yer

crying.

- Put a light coat of grease on

the part of the pistons which face the pad.

- No, you won't hurt anything.

Yes, grease on the pad surface or the rotor is bad but

you are not putting grease there. Put a light coating on

the backs of the pads. Just a LIGHT coating!

- Ok, now grease the leaf

springs, LIGHTLY.

- Grease the pin that holds the

pads in a bit. LIGHTLY. Just a nice light coating, helps

the pads slide on the pins, reduces corrosion ("rust"

for you simpletons).

- Now put the pads in the

caliper. CAREFULLY, you don't want the pad surface

touching any of the surfaces you just lightly greased.

- Ok, drain a little gas from

the tank, put the gas on a rag and wipe off the pad

surface and try again. Good, now it's all back together.

- Put the caliper onto the

rotor.

- Torque the caliper to the

fork slider. Yes, a whole 50Nm. No, I don't know the foot-pounds.

Foot-pounds are STOOPIT, get a torque wrench that reads

Newton-meters. Sheesh. Come on, Torquemada was Spanish,

he don't know nuffin'bout no footy-pounds.

- Yes, it's spozed to make that

sound when you torque it properly. NO, don't touch the

brake lever yet.

- Put some brake fluid, FRESH

brake fluid in the reservoir. NOT TOO MUCH!! You really

don't wanna fill it up all the way. Pump the brakes up,

slowly.

- Yes, if you pump it quickly

with the reservoir cap off it will shoot out brake fluid

onto your tank just like that. Best to pump slowly, with

the cap on and a nice clean WET towel on your tank. Yep,

that's it.

- Ok, now you feel some

resistance in the brake lever? Good. Take the reservoir

cap off, fill with brake fluid to JUST BELOW the top of

the sight glass.

- Push the rubber bladder

thingy in the reservoir cap back into it's non-expanded

shape.

- Put the reservoir cap back on.

Screw it down.

- Pump the brakes up. Release

the lever. Spin the wheel. It should spin freely with

only the slightest drag if any. Now, wasn't that easy?

You're welcome. Now give me my fifty bucks you twit and

get outta my way. Shank (eloquent as always, ed)

- Contrary to what Andy says,

my front tire has never spun for 15 seconds before being

dragged to a stop by the front brakes, not even when new.

I MIGHT get a few full rotations out of it on a good day.

If you've played around with your forks/axle lately, you

may have put the bike together with a slightly different

wheel position. I've done this several times while trying

to get the front wheel lined up properly. there's a

surprising amount of variation in how the forks will come

to rest with everything loosened up, and how they will

end up when you tighten the triple clamps, axle pinch

bolts and fork brace. and if you tighten things up with a

slightly different angle than you had previously, you can

get additional brake drag until the pads "seat"

themselves again to the new position. The last time I

straightened my forks in the clamps, after riding for a

long time with them just the slightest bit askew, my

brakes dragged horribly for a day or two, and eventually

everything was fine again. it may not seem to make much

sense, but the tolerance between the pads and rotor is

virtually nil and my experience playing with the fork

position has been consistent with it's temporary effect

on the brakes. As they say, YMMV. Mark #403

- Rear Brake riding the disc.

Yes, it's happened to me, twice. Each time I replaced

rear brake pads on my '99 Classic. There were two things

that were wrong:

Problem #1: The slide pins were sliding as intended.

Reason: Not greased properly at the factory (natch,

Italian bike).

Solution: Pull apart caliper, sand off rust on slide

pins, slather with copious amounts of BMW #10 (which I

find superior in resisting water and oxidation).

Problem#2: Caliper piston did not want to return to

"home" position all the way into it's bore.

Reason: Lots and lots of dirt, sand, mung, pigeon

excrement, and various other detritus indigenous to NYC

stuck to exposed sides of piston not allowing it to

recess fully into it's bore.

Solution: Take pads out, pump pedal SLOWLY and SLIGHTLY

to expose piston a little more than usual. Spray

profusely with lots and lots of highly toxic ozone-depleting

brake cleaner spray. Let it dry. Then cram pistons back

into the bore. Make sure that brake fluid reservoir is

NOT overfilled at this point. Which could also be a

reason why the piston would not want to recess fully into

it's bore.

A slight slather of BMW #10 (or axle grease or Auntie

Sieze's salve) on the backs of the pads (the part that

DOESN'T touch the brake disc) can keep the squealing pigs

of braking from singing their song. Good luck. Shank NYC.

- I've had problems with my

rear brake sticking, resulting in severe heat up, brake

pad wear and a potential fire hazard. It turns out that

dirt has gotten under the rubber boot of the rear master

cylinder and stops the master piston(?) from returning

completely. It's a warranty repair, including changing

the worn pads, since there is no periodic maintenance

prescribed for the master cylinder according to my dealer.

Hmm, being too impatient to wait for my appointment at

the dealer, having a slow day at work, and with a good

riding opportunity coming up this weekend, I decided to

have a look at the master cylinder myself. I won't have

the brake fixed by Friday if I don't do it myself, and I

won't do the trip without a functioning rear brake, so I

really don't care that much if I loose some Kroner worth

of warranty parts. After disconnecting and removing the

master cylinder, I tried to blow out the piston with

compressed air. No Luck. I then used a thin dowel (2.5 mm)

through the brake pipe connection at the top and

carefully tapped out the piston. The piston slides in a

nylon liner, and it seems this liner has become slightly

disfigured and pinches the piston so it couldn't slide

all the way back. I applied some Brembo mounting fluid

from the repair set for the rear master cylinder, (which

consists of a small gasket and a sachet of mounting

fluid, and is of course grossly overpriced), and

reassembled the cylinder. Working the piston up and down

inside the cylinder, I was able to take enough nylon off

to make the piston move freely again. I have no idea why

this has happened, but I suspect there may be some

corrosion of the aluminum behind the nylon, due to road

salt perhaps. Another option is that the cylinder has

been damaged in a fall when off-roading. This seems less

likely, since I always fall down on my left hand side (no

kidding (well, there was this one time...)). Sorry, no

pics. I don't have a Digital camera (yet). Perhaps the

most important lesson to be learned is to also check the

master cylinder in addition to caliper and piston if you

ever experience sticky brakes. Removing the rubber boot

at the bottom of the master cylinder and looking up,

you'll see a white nylon sleeve and a black piston which

slides inside it, held in place by a locking ring. The

piston should slide all the way down to the locking ring

when the brake is released, if not the brake fluid will

not be able to return from the caliper and the brakes

will stick. As the sticky brake heats up, the brake fluid

expands and increases the pressure and thus the braking

action. I reckon whoever it was that reported their rear

brake on fire a week ago (?) must have had the same

problem with the master piston not returning completely.

Oyvind #1052, Norway.

- Next.

Other reasons for Brakes heating up

Caliper

out of Alignment

Problem: Caliper torture. I

already have a warped rotor, I confirmed I have a minor hub warp

(.05-.06mm) problem, and I don't want to tighten the rotor any

more than I have to, as I have had previous problems with rotors

warping due to overtightening. I'm trying to shim the mounting

points (actually, just 1 or maybe 2 spots) on the hub as flat as

possible, before I tighten the rotor to it, and the rotor starts

going thru heating and cooling cycles. I'm tempted to go for

Loctite 243 (for removal without heat) and maybe 10Nm. But I did

measure, and it looks like the longer GS will fit the Classic,

and if I ever have to do this again I will order the longer bolts.

I've been looking at those seating clearances also. They might be

affected if the spacer were the wrong thickness (unlikely), if

the wheel bearings weren't fully seated (mine are fully seated,

crushing/holding the wheel bearing spacer in place, OR if the

rotor mounts cut into the wheel hub are machined too deeply,

causing the rotor to be seated farther inboard, which is what I'm

think may be my problem, but is much harder to check without

disassembly. If that was the case, I could make the axle spacer

on that side a few mm thinner to shift the rotor outboard. As it

is, for my caliper to fully release off the inboard side of the

rotor, the caliper has to slide inboard EVERY SINGLE BIT that is

available, including compressing/crushing the slide pin guide

bellows. When the bellows expands/pushes ever so slightly (we're

talking about less than a millimeter), as is it's rubber nature,

the caliper binds that tiny bit.....actually the front caliper

releases even less, and binds more, but has never even gotten

warm to the touch, despite the rotor getting hot when used hard.

If the rear caliper weren't so consistently too hot to touch, to

the point where I worry about the rubber seals, I'd ignore it.

The brakes have always worked perfectly, except for the heat. And

without actually dissembling the caliper (which I won't do unless

I have spare seal rings) I've tried all my tricks - I've flushed

the caliper 4-5 times, expanded out the pistons and cleaned/sprayed

them, removed the slide rubbers, cleaned them and tried 3

different hi temp caliper greases (synthetic and non synthetic)

on them, crushed them shut and bled out the excess air and grease

from the sliders, used older thinner pads which give me an

additional mm of clearance, used new OEM pads with new clip and

pin hardware, checked the release freeplay on the master

cylinder, and retracted the pads, filled the master cylinder

halfway, sealed it, and then pumped the pads down, creating a

minor vacuum in the m/c. I've serviced plenty of disk brakes, but

I'm at a loss on this one..... maybe a stupid question - I'm not

used to Brembos. I've been reinstalling my cleaned greased slide

rubber bushing by forcing it into the caliper hole, and then

installing the base plate slide pin, then bleeding the bellows as

I crush the caliper. You aren't supposed to place the slide

rubber on the pin and THEN force the rubber thru the caliper hole

are you? Seems hard to do without lubing the outside of the

rubber to go thru the caliper hole, like you'd tear the pin thru

the rubber. I dunno - no hurry, but clever ideas are welcome.

Otherwise, I just freakin love my bike! HsN

Solution: None.

Brakes work for about 50 applications and then it

grabs the disk.

Problem: I got a 2001 F650GS,

as far as I am concerned it is a lemon. Any way, was riding to

work yesterday, stopped at the light and I can smell this sharp

burning odour. looked at my rear brake and my calliper has smoke

coming out of it. I did notice earlier that the bike is kind of

sluggish, but did not think much of it at the time, riding in

city traffic and all... My rear calliper seized I thought, so I

took the screwdriver out of the bike kit and to my surprise I was

able to spread the shoes with little effort, that goes for the

calliper itself, it was free to move. I do have excessive travel

on my brake pedal, brakes work for about 50 applications and then

it does the same thing (grabs the disk), ABS work. One thing I

noticed that when I apply and release brake I can see the piston

move back and forth about 1/16".There is no way it should

move that much, at the time when brakes will not release the

brake pedal feels solid, like it was from new. Any thoughts? I

think it might be the master cylinder, or some kind of check

valve in ABS system. Pooshkin '01 F650GS, Winnipeg, Canada.

Solution: Just about a month later, I finally got all new

rear braking system:), dealer had no clue what to do, did not

care about what I had to say. I got new disc, caliper, shoes,

master cylinder, they had to take parts off a brand new bike. It

was getting pretty strange what it was doing, the bike was

applying rear brake by itself. Pooshkin '01 F650GS, Winnipeg,

Canada.

Feedback:

- Brake fluid is hygroscopic,

absorbs water from the air. Consider changing your brake

fluid and then bleeding the system if necessary. Flash #412

- Wonder if you have water (steam)

or air in the system (soft pedal) that expands

significantly as the fluid gets hotter due to use. At

some point, the brake starts dragging, creates heat which

expands the fluid, creating more brake pressure, more

drag, more heat, etc... I think I'd try a brake bleed

using fresh brake fluid first (but BMW "claims"

you need their special vacuum brake bleeder to do this

properly). Lots cheaper than ripping into BMW's "black

boxes." Marty #436-Chicago-97 F650F

- It's almost certainly a

problem with your master cylinder, AND it's a warranty

item. There's a white plastic sleeve inside the master

cylinder. I had corrosion between the cast metal body and

the plastic sleeve. This made the diameter of the plastic

cylinder slightly smaller, preventing the piston from

retreating completely when released. Thus, the fluid

can't return to the reservoir, causing the problems

you've described. It was fixed under warranty, and the

mech filled the rubber boot with grease. This has do far

prevented any more corrosion from occurring. Oyvind #1052,

'01 F650GS Dakar, Bergen, Norway.

Brake Calliper Retaining Bolt Warning

IMPORTANT: If you ever remove the

Front Brake Calliper for any work, Steering Head Bearings, Fork

replacement, whatever, make sure the Bolt threads are

clean and there are absolutely NO bits of Aluminium or any other

dirt or swarf jammed in the threads. If there is, use a fine

screwdriver and a wire brush to clean them thoroughly. In

addition check there are no bits of Aluminium in the threads of

the Calliper itself. Test that it can be wound all the way in BY

HAND before tightening. If it jams going in by hand, take it out

and check it and clean it again until you CAN screw it in BY HAND.

The reasons should be apparent, however any small amount of

Aluminium in the thread will start the bolt jamming. If you

tighten it further with a socket or spanner, it can't screw in

any more and starts ripping threads out. Then with more Aluminium

now jammed in the threads, as you back it out it rips even more

Aluminium out. You do not want this to happen. Really Bad

Karma. Do not exceed the specified torque.

Why Does my Brake Pedal Pulse ?

3 Reasons:

- Loose Brake Pedal Axle.

- Worn Roller. See The Chain Roller FAQ

- ABS Activation

Loose Brake Pedal Axle (Most

Common)

- If your chain is too loose,

particularly if your brake pedal bolt is too loose (because

the lower chain roller is on the same bolt) you can feel

the chain bouncing off the roller via the pedal. Take a

look at the bolt and the chain slack. Costs nothing to

correct if it is the problem and wastes virtually no time

to check if it isn't. The Allen Key Screw to do up: (i.e. the Brake Pedal Bolt). Flash#412

Missing lower chain roller.

- My chain is rubbing against

the chain guard attached to the brake pedal which is

resulting in a pulsating feeling in the pedal. The chain

is giving the recommended 20mm and I just lubed and

tightened the screw for the pedal and chain guard. If I

tighten the screw too tight, which appears to be the

answer, the pedal won't return far enough to disengage

the brake light.

ABS Activation

- ABS activation may cause the

brake pedal or lever to pulse, this is normal, but will

only occur under harsh braking on low grip surfaces.

Peoples first ABS stop can be worrying. There have been a

number of incidents with Landrovers in the late 80's when

people felt the ABS pulse and stopped pushing the pedal.

The wheels don't lock if you do this, but its generally

unhealthy. Andy #982

Front

Brake Play

See the Cable FAQ

Sources of Aftermarket Brake Calipers,

Rotors, Brake Lines

Terminology:

Floating rotors are not

"attached" to the rotor carrier. There are "half

holes" in the rotor and the carrier and there are rivets

that keep the rotor positioned in the carrier. They have a slight

amount of wiggle room. The REASON is so that when they get hot,

they can expand without warping because nothing is NAILED down.

They are free axially only. Draw two concentric circles. On the

inner circle, draw a set of six or eight tiny circles, spaced

equidistantly. Now, cut out the tiny circles. Then cut on the

inner circle. The piece from the outer to the inner, with the

tiny circles, is what the actual ROTOR part of a floating rotor

looks like. Now loosely rivet it to the inner circle at the tiny

circles and figure out how to mount the inner circle to your hub

and you have a floating rotor assembly. Get it? Floating calipers

are free to move across the thickness dimension of the rotors, to

adjust their position as the pads wear. The two "floats"

are orthogonal and therefore can be used in concert or

individually, as you like. Flash #412

OEM Brakes:

Our front Brakes are 30/32 mm Two

Pot Brembos and the rear is a single pot 34mm Brembo.

The Caliper No's are F 22.5553, R 22.5546.

OEM

F650 Classic Part#:

Front:

Disc Part # 34 21 2 345 323

Brake Caliper # 34 11 2 345 319

Rear:

Disc Part # 34 21 2 345 314

Brake Caliper # 34 21 2 345 312

OEM F650 GS/Dakar Part#

Front

Disc Part # 34 11 2 345 824

Brake Caliper # 34 11 2 345 854

Rear

Disc Part # 34 21 2 345 314

Brake Caliper # 34 11 2 345 856

Frenotec has OEM Brembo Parts, but doesn't

specifically list the BMW F650. It does say "New cast

caliper with 4 individual pads. Provides better braking pressure

and feel than older style calipers. Will upgrade most Ducati,

Aprilia, Moto Guzzi systems". If you find one that fits,

please let us know , ed!

Aftermarket Brake Parts Sources:

Brakes -

Aprilia:

- The Aprilia Pegaso, being

almost the same bike as the F650 Classic, has Rotors that

could be used as replacements.

Brakes -

Braking: www.braking.com

- I have my fingers crossed

that Dennis Kirk will be able to get me a BRAKING rotor

for about $125. (I think that's BRAKING part # front

rotor AP13FL and rear rotor BW05RI). Haven't found a

price from a Brembo dealer yet, if you happen to know any

that are retail friendly. http://www.braking.com/Eng/DISCHI.HTM. Todd#389

Brakes -

Ducati:

- Apparently the Ducati Monster

has the same Brembo Brakes as the F650.

Brakes

- EBC: www.ebcbrakes.com

- When setting up an extra set

of wheels for our 01 GSA, I ordered the EBC rotors and

sent them back after finding that the rear (?) wasn't

compatible with the ABS sensor plate. They also looked

like they belonged on a mini-bike, as far as finish was

concerned. I ended up using Braking rotors, front was a

floater, for the carbed model with no problems. Did you

need to do any adaptation to get the Braking rotor to

work with ABS? Not at all, bolted right on. No problems

and looks better than the OEM's, and still cheaper too. I

bought through Dennis Kirk. Iceman.

- www.accwhse.com has EBC

rotors for the f650 for $200 front, $130, rear. according

to the website, these are floating rotors. the number

below is for the front. the rear can be found by looking

up "profiles" on the accwhse.com website and

looking for the BMW F650. (60506) $199.95 EBC Rotor Left

#MD650LS Mark #403.

- Despite the BMW fiche part

numbers being different, the EBC catalog specifically

lists their rotors as fitting across the F650 line,

meaning the EBC front fits all years Funduro/ST/GS/CS

front, EBC rear rotor fits all years Funduro/ST/GS/CS

rear. Not sure about the calipers. It might mean the

Classic/GS rotors might be different, but

interchangeable? I'm about to break down and order a

Braking rear rotor as a replacement, the cheapest

alternative I've been able to find. Never used the brand

before, but I can't see waiting 8 weeks for a Galfer (which

is competitively $, but backordered). HsN

Brakes

- Galfer: www.galferusa.com

by Todd#389

Q. Can one

use a floating rotor (which Galfer offers as an option ) WITH a

floating caliper (like we have on the F650)? I always thought it

was either/or, but I ain't owned any fancy bikes.

- In my quest for what's

available to replace my slightly warped rear rotor, I

emailed Galfer USA (below) to ask what they have

available for replacement F650 rotors, and got a reply

from their agent, Cyclebrakes, with some part numbers (not available on

their website) that might be useful in the FAQ's. The

stuff isn't cheap, tho the Galfer floating front rotor

sounds interesting, competitively priced the same $176 as

an OEM rear rotor from CalBMW. I have my fingers crossed

that Dennis Kirk will be able to get me a BRAKING rotor

for about $125. (I think that's BRAKING part # Front

rotor AP13FL and Rear Rotor BW05RI). Haven't found a

price from a Brembo dealer yet, if you happen to know any

that are retail friendly. Hey, since the Motorworks and

Motobins websites list rear rotors for 60-80 UKPounds (cast

iron and OEM), considering the weight, I guess shipping

could justify much of the $40 difference compared to a US

price for an OEM rotor? btw, the www.cyclebrakes.com

website lists some interesting items I haven't seen

offered elsewhere, including thumb-brakes and Galfer

brake fluid. I hope some of this is interesting/useful,

helpful comments welcomed.

Reply from Cyclebrakes below:

Hi Todd,

We were forwarded your inquiry from Galfer as we handle

their retail inquiries and orders. We also carry EBC so

between the two manufacturers, we have stuff for your

bike in stock. Ready to ship is a Galfer Front Rotor with

Free Black, carbon-semi-metallic pad (or upgrade), Galfer

or EBC rear pads and EBC Rear Rotor (pad not included).

Galfer carries a front rotor, #DF663, in stock, $175.99

includes Free Black pads, #FD172 on current sale. You may

upgrade to Kevlar or Sintered HH pads for only $20 per

caliper. It is a FLOATING rotor which means better

performance and less chance for warping. #DF703 not in

stock, will have to request from Europe which is 6-8

weeks if they have it ready to ship, $159.99, also

includes Free Black pad, #FD165. Again, you may upgrade

to Kevlar or Sintered HH pads for only $20 per caliper.

EBC front rotor, #MD650, not in stock, $155.99 ETA 1

week, may not be floating (haven't seen a picture) Rear

#MD651, $155.99 in stock. If you want EBC pads then they

are front, #FA209 and rear, #FA208 both available in

sintered HH, $36.99 per caliper. EBC rotors do not

include Free Pads.

We also have Galfer steel-braided brake lines: FK003D166

front and rear, $53 for front and add rear only $40 with

free color choice on plastic outer sheath: red, blue,

yellow, smoke, black or clear.

To complete your order we will need: ORDER INFORMATION:

Bike Info and parts desired. Name & Phone Number,

Credit Card Number (Visa/MC), Ship-to address, Billing

address (where CC statements are sent) if different from

shipping, address, We make every attempt to ship same day

and we're located in southern, California. This quote is

good for two weeks.

Thanks for your request,

Take care,

Melissa

Phone: 805-452-5957

Fax: 805-653-5016, Attn: Cycle Brakes

sales@cyclebrakes.com

www.cyclebrakes.com

Brakes - Harrison: http://www.billet.co.uk/

Direct Links to

Harrison's F650 Specific Pages

"Thanks for

your mail Kristian. Apols for the delayed reply. The caliper that

we make specifically for the F650 (front only) is the #235. It

has 54mm spacing on the mounts. As far as we know the fitment is

the same for the "Classic" f650 and the newer F650GS,

but would like to have a confirmation of any differences if any

of your riders are knowledgeable on the subject. Our caliper is

direct fit, and designed to work with the factory disc.

We will be updating the website shortly, but the fitment is

currently posted on the 'new products' page.

Prices are (GBP£ excluding courier and VAT if applicable):

Billet Original facia design:

6-Piston Polished £239 each

6-Piston Clear or black anodised £259 each

'2k1' or New 'Signature' facia design:

6-Piston polished £271 each

6-Piston Clear or black anodised £289 each

Robert"

- Money spent on braided hoses

and aftermarket pads will give the most improvement for

money spent. If you like spending money Harrison billet

now has a 6 piston caliper (about $450) and there is a

320mm front rotor available. Not sure if these parts fit

the newer GS series but they do fit the original 94-2000

classics. Peter Jensen #233

Brakes - MAP Engineering: www.map-engineeering.com

- MAP Engineering makes an

oversize front rotor for the older 650 that I swear will

fit the Dakar. But MAP remains un-convinced. At least

that was there story when I wanted to buy one last summer.

Jinx

Brakes - Motorworks:

- Motorworks can supply Italian disks or cast iron ones.

If you want performance over looks go to the iron.

Remember you'll need new pads too, its false economy not

to change as a set. Aprillia dealers can probably supply

too. Andy Leeds UK #982

Brakes - Nagesti:

- This link will lead you to a

Japanese company that seems to make replacements for

everything under the (rising) sun. if nothing else, this

link has dimensions for everything as well. http://www.nagesti.com/ng/ingles/index.htm Mtbiero (cugino Pegaso)

Brakes - Spiegler:

www.spiegler.de

- A high-end German

manufacturer of brake parts, 8piston callipers, rotors,

some handlebar/foot-peg items that we all dream about,

with some US dealers. Even for the F650. Downloadable

catalogs w/prices. www.spiegler.de/gb/index.html

Feedback on Aftermarket Brake Parts

AM - Calipers

- Pegaso Cousin Offers Thanks.

What a great forum you have here. thanks for all the help.

This is what I have found recently that may be of

interest. I've been looking into upgraded calipers for my

Pegaso, and the best I can find to date is a commitment

from Harrison Billet in England that they will have a

unit for the F650 next month. I know the Pegaso and F650

share rotors, but before I drop major money on a 4, 6 or

8 piston caliper, I would really like to know if we share

calipers as well. The Brembo part number on my caliper (visible

from the back side, looking thru the spokes) is:

22.5553

This is a two piston single action/floating caliper (both

pistons on one side) style Brembo. It is common on KTM's,

husky's, Husabergs, Cagiva and other Euro Enduros. Is

there a kind soul out in F650 land that is willing to

take a peek at the backside of their front caliper and

tell me the part number (Brembo, not BMW). Thanks.

Prices FWIW:

Harrison 4 piston #173 ~= $260

Harrison 6 piston #214 ~= $321

Beringer 4 piston #240 ~= $460

Spiegler 4 piston $437

Spiegler 8 piston $491

There doesn't seem to be any opposed piston caliper

advertised as a drop in replacement (yet), however, http://www.jacklilley.com/jlcart/ lists supermoto caliper kits from

Beringer for Husky's, KTM etc, that may fit, but they

haven't responded to my e-mails yet. Spiegler has caliper

kits that will fit, but take an intermediate bracket. In

looking at a Brembo specs page at http://www.redracingparts.com/en/english.htm together with some application

info I got from http://www.tawvehicle.com/brembo.htm.

I think the latest Brembo 4 piston series, the "6800"

series with part numbers like 20.6800.x5 could be made to

work in place of the 22.5553 caliper, with a simple-to-fabricate

flat hanger plate. this is yet another option, however

I'll hold out for the Harrison as our calipers are the

same. mtiberio, DOD #1010, Former AMA Pro Twins National

#10, 4 time WERA Super Vintage National Champion.

- Frenotec ( www.frenotec.com ) has OEM Brembo Parts, but

doesn't specifically list the BMW F650. It does say

"New cast caliper with 4 individual pads. Provides

better braking pressure and feel than older style

calipers. Will upgrade most Ducati, Aprilia, Moto Guzzi

systems". If you find one fits, let us know!

- Checking http://www.tawvehicle.com/calcross2.htm#BMW cross-reference list doesn't

give any BMW F650 Caliper Part.

- Redracing do not have them either:

Reply-To: <red@redracingparts.com>

From: "Giovanni Bertone - RED Racing Parts"

<red@redracingparts.com>

To: "'Kristian <snip>

Subject: R: Calipers for Brembo Brakes

Date: Sun, 4 May 2003 14:44:31 +0200

Organization: RED Racing Parts

I'm sorry but we don't sell this calipers.

Best Regards

Giovanni Bertone

RED Racing Parts

red@redracingparts.com

www.redracingparts.com

> -----Messaggio originale-----

> Da: Kristian snip [mailto:snip]

> Inviato: sabato 3 maggio 2003 6.41

> A: red@redracingparts.com

> Oggetto: Calipers for Brembo Brakes

>

> Hi,

>

> I help write the FAQs for faq.f650.com. We're

looking for replacement Brembo Calipers. Our front Brakes

are 30/32 mm Two Pot Brembos and the rear is a single pot

34mm Brembo.

> The Serial No. on the Brake is F 22.5553, R 22.5546

>

> Do you stock this Caliper?

>

> Rgds

>

> Kristian

AM - Rotors

- While the BRAKING rotor is

not actually installed yet, it's fit and finish seem good.

Compared to OEM it has slightly smaller "feet"

meeting the hub, and machined completely flat. Double

sealed tamper resistant factory packaging. But I thought

it was interesting that there are easily TWICE as many

ventilating holes in the BRAKING rotor as compared to the

OEM rotor. That might be interesting. HsN

- Despite the BMW fiche part

numbers being different, the EBC catalog specifically

lists their rotors as fitting across the F650 line,

meaning the EBC front fits all years Funduro/ST/GS/CS

front, EBC rear rotor fits all years Funduro/ST/GS/CS

rear. Not sure about the calipers - takes me forever to

download the .pdf to view the applications.

It might mean the Classic/GS rotors might be different,

but interchangeable? http://www.ebcbrakes.com/.

- Next.

AM

- Rotor Bolt Sizes & Torques

- Q. The Classic Factory

Manual says to use Loctite 270 and 12Nm on the rotor

bolts. I never actually looked at that before,

assuming that the 270 was actually the Loctite 262 (red,

maximum strength, and often requires heat). Not so -

Loctite 270 is a PERMANENT maximum strength green

threadlocker that ALWAYS requires heat for removal. Like

for setting studs. My rotor bolts were certainly not set

with 270 as they came off so easily you could have used a

folding pocket wrench set. So I looked in the GS .pdf

manual (old edition), and there it says to use good old

basic Loctite 243 and 9Nm, as opposed to the 12Nm for the

Classic. What gives? Especially since the rear rotor on

the Classic and the GS are identical part numbers,

certainly fastened by similar size bolts, why new lower

torque's? I think that green Loctite 270 is overkill for

this application, and it certainly wasn't used on mine.

Except that BMW specifies otherwise, Loctite 262 is my

goop of choice, as an upgrade from 243, BUT lowly 243 is

specified in the GS .pdf. Any comments on the change from

12Nm to 9Nm? All obscure trivia, I know, but maybe worth

sharing with other aficionados? So, any enlightened

choices between 12Nm and 9 Nm on the bolts? I'm thinking

of 9Nm and Loctite 262, to lessen warping and yet obtain

better threadlock. HsN.

Thanks very much for the confirmation (Below). I find it

interesting that they changed both the specs (Loctite and

Torque) DOWN. HsN

- A.

- I checked the new GS manual

and it says to use LocTite 243 both front and rear, with

9.0 Nm.

- The bolts for the GS-GS/

Dakar are M6x20 and for the Classic M6x16.

- I checked some torque tables

I have and here is what found regarding M6 bolts

| Bolt Quality (Strength Rating) |

8.8 (Low Tension-Standard

Hardware Store Bolts). |

10.9 (Medium Tensile Strength -

Medium-Stress Applications) |

12.9 (High Tensile Strength -

Special Applications) |

| Molybdenum lubricated: |

8.9 Nm |

12.5Nm |

15.0 Nm |

| Clean and dry: |

10.5 Nm |

15.0 Nm |

17.5 Nm |

- The reason for the lubed/ dry

differences is to compensate for the friction / torsional

stress so that the "clamping" force is equal.

- You said you have socket head

on yours - on my GS there is Allen screws with short head.

Re: my torque table, almost all Allen screws is 12.9

quality. but due to the often-sharp corner under the head

they are best torque as 10.9 screws. All short head Allen

screws MUST be handled as 10.9 or less, despite the fact

that the material usually are heat treated to 12.9

tensile strength. I would think 9Nm is to be used on the

later models, not because of the bolt quality, but rather

because of the "weak" point here: the aluminum

hub. It is all too easy to strip threads in aluminum, if

the latter have inferior or "standard/ inexpensive"

quality. The reason the low head Allen screws must be

less torqued is due to a design compromise. Because of

the low head, the bottom of the "hole" must be

so deep that the material remaining is thinner than on

the normal Allen screws. Haakon #626, Norway.

AM-Brake

Lines (or Are Steel Braided

Brake Hoses Better than the OEM Rubber ones?)

This subject is

like discussing OIL. There are 1001 differing opinions. Like the

OIL discussion, a cross section of these opinions is presented

here. You choose which camp you fall in.

Note: BMW

already (and only) installs steel brake lines on the F650 bikes

that come with ABS and then ONLY the front.

- I asked my BMW shop about

steel lines at my 6000 mile service and he talked me out

of them. Said they look cool, but don't offer any benefit

on our bikes. FYI

- Steel brake lines make a

difference. Anyone who says they don't has never

experienced the difference. In some cases it is dramatic.

When I put steel brake lines on my 2002 the difference

was amazing.

- On the F650 you can see the

stock line expanding as you increase pressure. If you

practice stops from 60 MPH using maximum braking and then

practice again using steel lines (especially the front)

you would have to notice a difference. Just my opinion.

- An SS-line on the rear is a

total waste, IMHO. On the front... like POWER BRAKES when

compared to rubber hoses. YMMV.

- SS lines still not needed!

Either end...Anybody can stop the bike as stock with

maximum efficiency. Only the most performance minded see

any good in these, as I'm one of those guys, but still

don't think they are needed. They do have an effect,

however, I agree. You'd better be good at your braking

skills if you need the extra performance.

- SS Lines greatly reduce the

effort needed to brake with one finger while descending a

hill standing up on the pegs (to lower the centre of

gravity!) This, IMHO, is worth the cost. The fact that

they last 5 times as long is just a bonus.

- Anyone who says SST lines

don't make any difference has never tried them. they make

the brakes have a much more linear feel in terms of

pressure applied to the lever equating to braking applied

to the rotor. The stock lines expand more as you brake

harder.

- SST lines are not needed on

any bike, so that's a moot point. but they do make a huge

difference in how the brakes feel. The SST line made a

bigger difference to him than adding the 320mm MAP rotor.

- Get the SST line, get some

good pads, like Galfer greens, change your fluid and

bleed your lines and you will never have anything to

complain about regarding the f650's braking capabilities.

My ring finger and pinkie haven't touched the brake lever

since I made those changes.

- I agree again, that they make

a difference, but are not required, because feel to one

rider is not the same for another. I've ridden both types

of lines and prefer the rubber hose and they last a long

time. Can't remember ever having changed a brake hose (stock

one). My braking ability is not diminished one bit

because the lack of SS lines. They are very nice and a

plus for some, but not all If you can lock the front

wheel, I say that’s all the feel you better have.

The stock lines will do that fairly easily. Just don't do

it. Some like a lighter feel on the brakes and its

accomplished with SS lines.

- Galfer Brake Lines:

The number on the box was FK003D166- don't know if that's

the part number or not. I got it from http://www.map-engineering.com/index.htm for my '99; it was around $45 plus

shipping last winter.

- For you guys asking about

brake bleeding: For the cost of one garage fluid change/bleed

you can buy an excellent vacuum bleeder or Speedbleeders

(and probably stainless lines as well) and do your own in

10 minutes. On our F's it's totally simple requiring no

wheel removal or anything. An SS-line on the rear

is a total waste, IMHO. On the front... like POWER BRAKES

when compared to rubber hoses. Flash #412

- I've installed both

Speedbleeders front and rear and a steel braided front

brake line on my f650ST 97. The problem is that to

install the brake line you have to empty the system and

then the speed bleeder won't work because there will no

pressure. So you have to fill up the system with the old

bleeder on, using a vacuum pump (speed bleeders don't

work with a vacuum pump), then install the speed bleeder

and process as described in the instructions. That goes

only for the first time because you have no reason to

empty the system afterwards. The rear, where I kept the

OEM brake line was a piece of cake. We did it on Tom #773

bike and mine and doing it yourself depends on your level

of self-confidence (I am in the process of building it...).

I guess the whole thing should not take more than 30

minutes at the shop so we're not talking about a lot of

money and if you don't feel to confident let a mechanic

do it. My 2 cents. Jean #636

- What you could do is install

your new SS-line and do the initial line-fill using the

stock bleed screw. After you've got fluid in the line,

THEN install the Speedbleeder for the final purge. Flash

#412.

- I had the unfortunate

experience of the most severe sphincter-sucking-up-seat-vinyl

stop in the life of my F650. I believe that if it hadn't

been for the new stainless line and the Galfers, I

would've gone up that SUVs tailpipe. And that would've

made my day quite difficult. Stainless ROCKS!! New brake

fluid is good. Galfers are AWESOME! Shank NYC USA

- Money spent on braided hoses

and aftermarket pads will give the most improvement for

money spent. If you like spending money Harrison billet

now has a 6 piston caliper (about $450) and there is a

320mm front rotor available. Not sure if these parts fit

the newer GS series but they do fit the original 94-2000

classics. Peter Jensen #233

- Front - The biggest

improvement was adding a braided steel line. The Dakar,

with it's 210mm fork travel, has a very long hose. Lot's

of flex. With a multi-day bleed job, it was much better.

Rear - I think a lot of the problem comes from wheel

alignment. I have become fanatical about alignment since

it appears to have a big effect on rear brake performance.

Even a little cocking of the rear rotor will cause about

half the efficiency to go away. I have heard good things

about after-market pads, but will wear out the stockers

first. (Cheap that I am). I am sure the stock pads were

supplied by the low bidder. With braided lines up front,

and maybe some EBC pads front and rear, I think the

brakes would be okay. And probably as much as you would

ever want off road. Jinx

- I've put on a braided line

and bled it which has made a difference but nowhere near

the result that I ultimately desire-I have to confess

that I haven't had a look at the wheel alignment issue

that was suggested - so there might be some gains to be

had without spending anything but time. I have only put a

braided line on the front because the Brembo dealer was

scratching his head over the routing of the rear brake

line-it looks pretty complex (or so he said), I will be

looking at it tonight (just as soon as I put the fuel

nanny on - but that's another thread). Ziegfried

- The old brake line on the

Dakar was a little too stressed to me due to the

handlebar risers... just a little too tight for comfort.

I replaced it this evening with a Touratech stainless

steel version. The difference, like others have said, is

night and day. Makes me want to beef up the front springs

now. Gerry #951 (Phoenix AZ).

- So I read about how it's a

good idea to swap out the brakelines for the steel

versions, and then realized that the front brake line on

my bike is already steel braid. Do they normally come

this way stock or did I just get lucky? I bought the bike

brand new from a dealer. '03 black GS, Colorado

- I believe that BMW only

installs steel brake lines on the bikes that come with

ABS. Apparently they believe that BMW riders are not

skilled enough to be able to handle the improved feel of

a firm brake line. In my experience, No. Your hands are

much more sensitive to feel than your foot, with the clod-hopper

attached. In any case, with weight transfer when braking

hard, the rear brake doesn't really need the same feel as

the front. The rubber hoses are OK, but they flex a bit

when used and tend to put a little extra give into the

brake feel. Steel brake lines are noticeable better, but

you won't notice the difference at the rear brake.

Richard #230

- The front is but have you

checked out the rear? My '01 model still has rubber hose

from the rear master cylinder to the rear caliper. I

think Touratech makes a steel line for the rear. That

said, lots of people don't care that much about the feel

of the rear brake. Brad, N. CA., 2001 F650GS - Inmate #1002

- Next.

Contact Area & Front Wheel vs. Rear

Wheel

Q. So, because I'm very

curious (its good I'm not a cat), I did some research on MC

Dynamics and believe I can summarize what I have read so far.

Please correct me if I am wrong.

Given an unlimited coefficient of friction at the front tire

contact patch and given that the COM (center of mass) of the

rider/MC system is higher than the center of the front wheel, the

MC will eventually tilt forward after shifting 100% of the mass

to the front wheel. For optimal braking the COM should be as low

and as far back as possible. I'll give a link for the source of

this info below.

So, assuming that the COM of the bike is a constant (ignoring

brake dive for the moment), then the rider's addition to the

calculation for COM comes at the pegs, handlebars, knees/thighs,

and bottom. Clearly, if we could get 100% of our mass while

braking at 1g on the footpegs (lower than the center of the

wheels) that would be great (its impossible of course). So, the

best we can hope to do with COM is limited by how far back we can

sit on the bike and still operate the brake lever while trying to

keep as much force off the handlebars as possible (get yourselves

a thighmaster). You need to sit as far back as possible to

counteract as much as possible the effect of the force put on the

handlebars (trying to tilt the bike over). The more weight you

can keep on the rear tire the more you can use its coefficient of

friction in addition to the front. Hopefully, I've gotten most of

this right...here's the link I mentioned: http://www.dinamoto.mecc.unipd.it/ Chris in Santa Cruz, CA #782 - 19-Mar-02

A. The basic answer is Yes!

Weight transfer needs to be balanced against what a brake can

absorb in terms of energy which is a combination of down force,

tyre contact area and the brakes ability to generate heat and

then get rid of it. Brake balance changes weight transfer during

the stop.

If things are uneven, you get events such as ABS activation of a

lifted wheel that will change weight transfer again and upset the

whole vehicle calculation.

Instrumentation consists of wheel speed sensors (like ABS),

vehicle speed (via radar) and pressure transducers in the brake

lines. Everything is plotted against time, so you can get vehicle

deceleration, wheel angular deceleration etc. Temperature

transducers are useful to sort vehicles that don't work as the

disk or drum temperature pretty much tells you how much work a