Pazzo's Adjustable F650GS Screen

Many thanks to Pazzo for allowing this to be

hosted on the CG. ed.

Updated 2004 06 17 by mspeed #1023

Let's start with the price: The cost for this

screen is in the $100 range (I paid €92 for it in Holland). The price itself is

already amazing: One easily has to pay over $150 for the average aftermarket

screen, so getting a BMW screen for this price is terrific. The screen has a

total length of over 20" and has a top section that is extra wide, with a curved

top to further deflect the wind. Just like the original 650 tall screen it is

made from cast polycarbonate. Being designed for the K1200GT it is certainly

strong enough to handle wind pressure up to the 100-some mile maximum speed of

the 650GS.

Design

The K1200GT screen has a bottom width that almost perfectly matches the

width of the 650GS standard silver wind deflector. The wide top not only allows

enough space for the 650 mirrors to pass when making sharp turns or locking the

bike in Park, but even accommodates my Dakar handlebar protectors. After

mounting the screen I was amazed how well it aligns with the 650GS shape, and

even my purist BMW dealer found it a very compatible solution. The "lip" at the

top further improves wind deflection and eliminates neck fatigue, allowing you

to drive multiple hours with high comfort. The screen is specified by BMW as the

"comfort windshield" (see part number below) for the K1200GT. Note: This screen

is slightly different from the comfort screens of the K1200RS.

Comparison with other screens

I've tested the Ermax screen and similar Dakar screen. They both are too

narrow and cause buffeting and have poor wind deflection. For that reason, I

modified the tall 650GS screen ("Trevor style") to make it movable. This

eliminated most of the buffeting but loses its effect above 75-80 mph. It also

is too narrow, so there will still be quite some wind on your upper body.

The GIVI screen is no different than the tall BMW screen, so no improvement. I

like the shape of the Wunderlich screen, but it is in essence not that much

different from the Ermax or Dakar. It further is rather thin and does not offer

the length to deflect wind above 70-75 mph.

The Parabellum is certainly more effective, but it has a poor match with the

650GS cockpit and also needs more work to mount.

Last but not least: The Cee Bailey's is a definitive step forward. With its 21"

height it is the right size, but the lower mounting and rather narrow top makes

it less effective and it is 40% more expensive.

The K1200GT screen beats all of the above screens by an order of magnitude. It

is manufactured by BMW with thick, high quality, cast polycarbonate. It has an

excellent fit, and does on the 650GS exactly what it does on the K1200GT:

Eliminate virtually all wind up to around 100 mph.

On the K1200GT, the screen is connected via four cast mounting handles to levers

that allow the screen to be either manually (K1200GT 2001/2002) or electrically

(2003/2004) lowered and raised about 4" to make touring more comfortable. These

four handles form part of the polycarbonate cast and offer a perfect match for

the connection to the 650GS (series up to 2003). The two lower handles are just

far enough apart to allow them to be attached to the upper screws of the

standard 650GS deflector via two "Z" shaped thin steel mounting plates, while

the two higher handles almost perfectly fit the metal bars that I've already

used for my earlier tall screen modification. Material costs for the

construction should be under $20. I started with a prototype that took an hour

or two to build. After driving several hundred miles with the prototype I

created the final version that is described below. With the drawings below you

should be able to build this solution in a few hours (excluding paint work).

Driving test and Conclusion

I have now driven with the screen for some 1000

miles without any problems. Of these 1000 miles, 600 were done in a single day

driving back and forth from Amsterdam to Frankfurt. Where, prior to this screen,

I would have been quite tired after riding this bike for almost 10 hours

(including a nice trip along the Rhine river, see pic below), I now felt great

and would do it again tomorrow.

For my 6 ft height the screen is ideal. I expect that the screen will probably

accommodate heights up to about 6' 4". I can drive with open visor and without

earplugs at speeds up to 100 mph. No buffeting or other wind problems. The wide

top also deflects the wind from the upper body, and eliminates side winds when

making turns at high speeds, which are nice extras. The construction is very

robust and has survived some basic off-road driving. Another side effect: The

larger screen puts more pressure on the front wheel at high speeds and therefore

reduces the tendency to 'lift'. Play around with the height of the screen once

you've installed it. I noticed that the wind deflection from the curved top

actually is better when the screen is a bit more horizontal (=higher wind

speeds), so maximum height does not always mean minimum wind.

Needless to say this has significantly increased my pleasure of riding the

650GS, allowing me to hop on without bothering about ear protection and having

comfortable long drives even in light rain, as nearly all wind and rain is

deflected by the screen. One remark, based on experience: The curved top

deflector was created to deflect wind only. Mosquitoes at 100 mph will not be

much deflected, so eyeglasses are advised when you plan to drive with an open

visor at these higher speeds.

Good luck and many enjoyable driving hours at 100+mph!

Gert ("Pazzo") 2004©AntarticaGalleries

Construction

Start with the screen: It is the tall version of

the screen for the K1200GT. BMW part number: 46-63-7-663-115 (in US $ 91.50)

All other parts are depicted below. The nuts and bolts depicted below are self

explanatory. You can reuse the screws from the standard 650 silver deflector.

For the other screws you can use allen or other types, as long as they are

stainless steel. The wing nuts and nylon washers should be supplied with the

window brackets.

The two brackets on top are tall versions of the ones I used for my earlier

modified version of the 650GS screen. They are brackets used for opening doors

and windows and should cost you around $12 a pair. They are almost 14" long and

1/8" (3mm) thick. They're made of stainless steel.

Underneath the brackets, on the left hand side, you'll see the two polycarbonate

(lexan) braces that connect the top two handles on the screen to the metal

brackets. The wing nuts are mounted on the side of the brackets, and allow you

to raise the screen to fit your length and lower it when you plan to do some

off-roading. I initially used metal braces, but found the polycarbonate braces

cosmetically nicer. They are just as easy to make from some scrap polycarbonate/lexan

and offer additional flexibility, therefore putting less stress on the screen

handles when you're off-roading.

On the right side of the above image, under the brackets, you'll find the screws

with small plastic spacers that connect the brackets to the bike, replacing the

screws just behind the Turn Signal mount screws (so, the 4th screw). The spacers

(used in cabinets) provide the extra distance so that the brackets won't rub

against the grey plastic fairing.

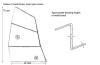

In the middle of the above image you'll see two "Z" shaped mounting plates that

you'll need to make from thin steel (1 mm, or 1/16"). Make sure you use steel.

Aluminum will not be able to sustain the bike's vibrations or needs to be much

thicker. Bending these braces in the proper shape is the only key activity that

is needed, so take your time. To assist you with this work, I've created a model

of the "Z" below. If you're not comfortable using this model, don't hesitate to

make your own model from a piece of cardboard. It only takes a few minutes to

cut a model and it helps you understand its shape and the fact that the two Z's

need to be mirror (!!!) image.

The "Z" plates are used to connect the top screws of the silver wind deflector

to the two lower handles on the K1200GT screen. The reason for having the "Z"

shaped profile is that I expect that, sooner or later, one of these handles of

the K1200 screen may crack or break. This happens sometimes on the K1200GT when

people try to adjust the screen at 130 mph, is what my BMW repair shop told me.

While constructing the mounting plate you only need to spend a few extra minutes

to bend the "Z" shape, rather than creating the more simple "L" shape. Should

one of the handles of the screen come off you can mount the screen again by

drilling a small hole through the screen into the mounting plate and using the

nut and (self-locking) bolt to fix it again.

Use the model below to obtain the correct scale for creating the mounting plate

(apologies for using metric here: 75 mm equals 3") and bend the plate according

to the Z-shape on the right hand side of the drawing. I made the mounting plates

from a single steel joist hanger with width of around 3˝ " and similar bearing.

They're available in any Home Depot or equivalent shop for under $2. After

cutting the basic shape and bending it in accordance with the model, you'll need

to drill the two holes on the indicated spots. The only time consuming part left

is to (spray) paint them, but I suggest you only do that after you've tested

them with the screen. In that case you'll need to be a bit extra careful with

the screen. Polycarbonate/lexan is easily scratched.

Polycarbonate/lexan braces mounted

Polycarbonate/lexan braces mounted

Joist hanger, two pre-Z's, and cardboard model

Joist hanger, two pre-Z's, and cardboard model

Mounted Z on bike

Mounted Z on bike

Z's need to be mirror image!

Z's need to be mirror image!

The wind screen

As a newbie I do not comprehend the excitement of

race bikers when there doing well over 200 km/h (120 mph). There is not a

windscreen that will protect you at these speeds, so the best way to drive at

these speeds is comfortably in your car (excuse me: I mean "cage"). My BMW 650GS

came with the tall BMW windscreen. Above about 80 km/h, no positive effect is to

be gained from this screen. I'm 1m80 (6 ft) and when I ride the thumper, the

wind hits me just under my chin. Riding 100 km/h is already uncomfortable and

140 km/h (90 mph) is quite unpleasant and only useful for some quick

passing.

As a newbie I had not realized this BMW screen was that poorly

constructed, so I started browsing the internet again to figure out a solution.

I found that there are three screens available (in Europe) that fit the (new)

F650GS: The tall BMW screen, the BMW Dakar screen, and an Ermax tall screen.

Multiple stories and theories existed on the web about these screens, with lots

of impressions but no hard data. In addition to the commercially available

screens there are also some non-standard fixes. I'll describe most of them

below.

How to improve your screen?

Based on info from the FAQ pages

of the Chain Gang, I

modified my existing tall F650 GS BMW screen by adding 12 mm (1/2") plastic

spacers under the top screws. I had to make the two side holes in the screen a

bit oval to allow for the new position of the screws. Easily done with a low rev

drill. The more upright position helped a bit, but not a significant

amount.

Wind impact point moved from my chin up to my nose (I'm 1m80 - 6 ft).

Big deal.

What to do next? Adding one of those little plastic winglets on top of my

screen (made by Saeng) did not make too much sense to me. I played around with

the idea to build the "jet compression" windscreen that was mentioned on the

Chain Gang site. This was a story that seemed to have appeared in a German

motorcycle magazine. When and where is not known and some charts that were

supposed to show why the system worked were no longer present.

The document can be found

here. It basically means that the author built a funnel on top

of his screen. The funnel increased the density of the air and caused it to

"blow away" the air that hit the screen from the front. Sounds logical, but how

to build one? I have seen a somewhat similar gadget on an older BMW, but that

strip was only 5 cm (2"). A funnel should be much longer to have any positive

effect.

Out of curiosity I posted the basics of this story at an aerodynamics

engineering site, just to see if one could design such system based on

aerodynamics theory. The feedback from the experts was that this theory about a

"23 degree air compression and expansion angle" was basically bullocks and that

there were too many variables existing for any decent planning of such screen.

Trial and effort seemed the only way forward, but if you realize that you will

have to buy LEXAN (as used by BMW) or some other poly-type material at $ 150 per

square meter, you'll need to make a mold for the form, and be proficient with a

heat gun or use a temperature controlled oven to bend these 5 mm thick screens,

you realize that this is not going to be an easy task. Expect to mess up at

least two screens and a few days of work before you may have a useable

prototype.

Earplug intermezzo

I admitted defeat and started to wear ear

plugs. That did ten times more for the noise than any screen will ever do.

However, I still would like to be able to ride about 70 mph without them. By the

way, I have been using Wilson pilot earplugs for many years on board the plane

(as passenger) to silence out the engine noise that causes most of the tiredness

after intercontinental flights. They cost virtually nothing. Last batch I bought

was at http://aircraft-spruce.com/main.html. Can't get any better and

they're only about $2.

Ermax versus BMW screens and what about "Jet

Compression"?

Anyway, having read multiple articles and comparisons

between the BMW and Ermax screen I decided to give the Ermax a try. I ordered

the "tall" transparent screen ($92 in Holland and had to be shipped from France)

and received it two weeks later. Note: Ermax did not ship the long M5 screws

that you need with the screen so I had to get these from my local hardware

store.

Key difference: The Ermax screen is far more upright than the BMW screen and

is a bit curved away from the screen at the top, which helps messing up the wind

speed. Note that the Dakar screen has a much more curved screen top. Overall

result is that the wind now hits me at the forehead: Altogether a 15 cm (6")

improvement ($16 per inch). Still not enough to ride with an open helmet, but a

little better when you're doing 70

mph. I did notice that the form of the

Ermax causes buffeting. The BMW tall screen does not have this problem.

My conclusion is that the Ermax moves the "quiet" zone a bit up, but not

enough if you're 1m80. I guess that Ermax caters for the French market where

people are still a bit less tall than in Norther Europe. You will still need ear

plugs. At speeds above 90 mph there is quite some buffeting. Everything

basically starts to get blurred at that speed. Side wind from the screen hits

the mirrors, which are sometimes blown out of position. If you're up to about

1m75 (5ft10) I expect the Ermax to be more effective than the tall BMW screen.

If you're taller and already have the tall BMW screen or the Dakar screen, the

Ermax is not worth the money. I noticed that the BMW tall screen is made from

LEXAN (polycarbonate) while the Ermax looks made of thick Acrylic glass. It took

only a day to get some scratches on the Ermax screen (and therefore couldn't

return it to the store).

No screen better than any screen?

I installed the Ermax

over the small stock screen that originally comes with the F650GS. While trying

to get the right type of screws for the Ermax I drove around for a day with only

the small screen, and concluded that up to speeds of about 50 mph it does'n

matter at all if you have a screen or not.

Altogether I'm still looking for a

more optimal solution. Now that I have two screens I will use the BMW screen to

apply the "Trevor adjustable screen" solution (see below).

Some screen theory

To get comparison numbers that can be

used for future reference I measured the height of the screen by taking the

distance from the top of the (fake) tank, a pretty stable element on my bike, to

the top of the screen (vertical measurement only). Results: The tall BMW screen,

unaltered, measures 32 cm (about 13") tank-to-screen top. My altered version

(adding some spacers on top screws) has 38 cm (little over 15")

tank-to-top.

The Ermax buffeting screen measures 45 cm (18")

tank-to-top.

Using the shape of the BMW tall screen I measured the maximum

height that Trevor's adjustable screen will be able to go: 44 cm tank-to-top, so

a bit less than Ermax. Trevor's height is 1m76 (5ft10.5), so that's why his

screen is perfect for him. Since I'm 1m80 (6 ft) I guess I need about 50 cm

(20") to be able to ride with less wind problems.

Rando

has made a screen from a large old Slipstream screen. This huge screen solves

all problems, so check out Rando's pictures. His screen measures just over 50 cm (20") tank-to-top and

should therefore be the right solution for me as well. Problem is how to get a

Slipstreamer screen (the right type of screen) in Europe in one week (I'll be

going away for vacation with the thumper for the "As the crow flies trip"). So the answer lies in trying Trevor's

adjustable screen.

My general conclusion from these measurements is that a very basic principle

applies: As long as the top of the screen is at about eye level you will have

significant less wind impact. It apparently does not matter very much how the

screen is shaped and whether it has the extra top spoiler or not. The easiest

way to see if your screen modification is successful (besides trying out) is to

tape some loom to the top of your screen and see what happens with these tiny

strings at different speeds. Raising the screen above your eye level is also an

option, but in that case you need to raise it substantially higher (at least 10

cm / 4") above eye level to avoid visibility problems. This last solution will

probably look a bit silly on an all-road bike.

The Trevor Screen Solution

I name it after the inventor of

this solution. Have a look at Trevor's site with nice shots of his adjustable screen.

It took me a while to find the right hardware store for the drawer brackets.

Most of them had newer versions based on a tube system. I started to collect all

applicable bracket types until I found window brackets that would probably fit

Trevor's description.

The

top two are window brackets (2 mm thick), the lower two are brackets for

cabinets. Looking at Trevor's site he used a longer version of the thinner "d"

type bracket. My preference was to use the "c" type (also 2mm thick), because

this is a single rod of steel and has a nice clamping system. The clamp,

however, could not be fully fixed in place so I'll defer this system for a next

round. The window brackets "a" and "b" were a bit too large, but had the

advantage of being very strong and reasonably weather proof. A nice extra was

that they already have all the necessary fixing material, including the wing nut

and nylon washers. The price for a pair of nr. "b" was a mere $10. The lowest

bracket is used for cabinets, has thickness of 1.5mm and is less

weather-resistant, so I opted for bracket "b".

The

top two are window brackets (2 mm thick), the lower two are brackets for

cabinets. Looking at Trevor's site he used a longer version of the thinner "d"

type bracket. My preference was to use the "c" type (also 2mm thick), because

this is a single rod of steel and has a nice clamping system. The clamp,

however, could not be fully fixed in place so I'll defer this system for a next

round. The window brackets "a" and "b" were a bit too large, but had the

advantage of being very strong and reasonably weather proof. A nice extra was

that they already have all the necessary fixing material, including the wing nut

and nylon washers. The price for a pair of nr. "b" was a mere $10. The lowest

bracket is used for cabinets, has thickness of 1.5mm and is less

weather-resistant, so I opted for bracket "b".

The work to transform two of these brackets into the components

to mount on the bike was no more than an hour work, and basically consisted of

sawing the M6 screw part from the bracket (see top row) and making the hole on

the left in the bracket (2nd row) a bit wider. Since my screen needed to be

about 5 cm (2") higher than Trevor's screen I added a hinge to the lower part of

the screen. I bought two hinges and preferred the right one, but used the left

one for this first prototype because this one was made of stainless steel. Price

for the hinge: $1.50. An additional advantage of the hinge is that it avoids

pressure on the screen when you adjust the height.

The work to transform two of these brackets into the components

to mount on the bike was no more than an hour work, and basically consisted of

sawing the M6 screw part from the bracket (see top row) and making the hole on

the left in the bracket (2nd row) a bit wider. Since my screen needed to be

about 5 cm (2") higher than Trevor's screen I added a hinge to the lower part of

the screen. I bought two hinges and preferred the right one, but used the left

one for this first prototype because this one was made of stainless steel. Price

for the hinge: $1.50. An additional advantage of the hinge is that it avoids

pressure on the screen when you adjust the height.

The brackets were a bit on the long side (30 cm - 12"), which I solved by

mounting them on the 4th screw into the silver plastic moulding of the 650GS. I

found this position a bit easier as it is behind the turn-light and therefore

easier to mount. Just like Trevor I used a 1.5 cm (1/2") spacer o fit the

bracket onto the screws and re-used the two tall screws from the screen to mount

these brackets. The hinge I mounted to the headlight structure using the third

screw from the screen. Besides the wing nuts which came with the brackets, I

therefore only needed to add one M5 screw to connect the hinge onto the screen.

This prototype still has a basic screw for the top mounting of the hinge. I plan

to use some nicer looking screws in a next version.

Note that I mounted the

tall screen on top of the stock screen. First of all because I found this better

looking, and secondly because the stock screen reduces the opening between the

tall screen and the lamp house and therefore reduces false winds. Worst case: If

my adjustable screen crashes for some reason during my long trip I always have

the stock screen to continue.

Below you'll see the low mount, with a cone-shaped plastic washer on the

inside (left) that sells as a small doorstop. The rubber washer on the right

side is a washer that is used in faucets. Low in price and very good quality

rubber. The middle picture shows the stock screen with hinge, and the right

picture shows the wingnut of the top mount on the inside of the screen. See

release 2 version on next page for an explanation.

A 6mm hole at the corner of the screen is easily drilled in the LEXAN. The

nylon washers that came with the window brackets fitted perfectly. I positioned

the wing nut on the inside of the screen, mainly for cosmetic purposes. I may

eventually replace the wing nuts by regular screws. The brackets needed a little

bending by hand to fit the curve of the screen. The result is given in the pics

below. Total amount of work was about 3 hours, most of which was spent in

explaining to other folks passing by what I was doing.

The two pics on the left are the "Hinged Trevor" screen prototype. The

picture next to that is the Ermax screen and the one on the right is the BMW

tall screen (modified with spacers). I adapted the size of the pictures somewhat

so that the "Mickey Mouse Mirror Ears" have about the same size. This shows the

substantial difference between the adjustable screen and the two other

options.

Future versions will have a prettier hinge, of course. That is a matter of

finding a stainless steel hinge with only a single hole and which then will be

shaped to follow the curve of the screen.

Prototype Driving Test

A noticeable reduction in wind at

helmet level! The tank-to-top distance of this hinged version of the Trevor

screen measures 51 cm (20.5""). I can drive 100 km/h (60 mph) without earplugs

and with the screen of my helmet a little open. Wind hits me at the helmet just

above the forehead and has much less power. This does not mean that there is no

wind at all, but it is sufficiently less to take short trips (30 minutes) on the

highway at this speed without ear plugs. With earplugs, speeds up to 130 km (80

mph) can be driven without too much buffeting. Because the upright screen is a

bit further away from you there will be some buffeting, but the quantity is

tolerable and much less than with the Ermax screen. The opening between the

stock screen and the tall screen does not lead to false winds from below. In its

highest position, the screen is just at eye level. I found that having the dark

edge of the screen at eye level disturbs my vision on the highway and have

therefore lowered it about an inch.

Altogether, Trevor's adjustable screen is a success! The modification is very

inexpensive and can be done with basic tools and without being an experienced

handyman. The adjustability of the screen will allow you to lower it quickly

when you're planning to go off-road and want to get rid of the screen. You

should not expect miracles from this modification, but the improvement is

significant enough to give it a try when you're tall and like to ride over 100

km/60 mph with some more comfort. Worst that could happen is that you have

wasted a few dollars in brackets and end up with two little extra holes on the

side of your screen.

What's Next?

Improvements:

- Make the hinge better looking. I

already closed the other screw-holes with polyester and will paint it light

gray/silver and see if that looks better.

- Replace the screws in the top

mount of the brackets by short slotted screws that fit the opening in the

brackets. This means only the wing nuts need to tightened on the inside of the

screen.

- Have both the brackets and the hinge galvanised for permanent rust

protection. This is an inexpensive job, but usually has a return time of a week,

which I do not have presently.

- Now that this works for the tall BMW screen

I can try to do something similar with the Ermax screen that I now have as

spare.

The

Prototype Release 2

After two of days driving I found the time to make a couple of improvements.

Top Mount Screws

These

used to be composed of a screw and the wing nut. I replaced the screw by a bolt

that locks into the bracket. This eliminates the need for a tool when adjusting

the screen. The wing nut can be loosened by hand and adjusting the screen is a

matter of seconds (but don't try this while driving). The special bolts will add

the serious amount of $1 to the costs.

These

used to be composed of a screw and the wing nut. I replaced the screw by a bolt

that locks into the bracket. This eliminates the need for a tool when adjusting

the screen. The wing nut can be loosened by hand and adjusting the screen is a

matter of seconds (but don't try this while driving). The special bolts will add

the serious amount of $1 to the costs.

The Hinge

Now

that the prototype worked out OK, it was time for some cosmetic changes. The

unused holes were filled with polyester compound (left from an older car restore

project) and spray-painted a couple of times with rust-protecting silver paint.

The spray can cost $ 12, but this will be good for the next 100 hinges, of

course. The picture was taken after one of those typical Dutch rainy summer days

(and winter is worse). The paint was only one day old but held good.

Now

that the prototype worked out OK, it was time for some cosmetic changes. The

unused holes were filled with polyester compound (left from an older car restore

project) and spray-painted a couple of times with rust-protecting silver paint.

The spray can cost $ 12, but this will be good for the next 100 hinges, of

course. The picture was taken after one of those typical Dutch rainy summer days

(and winter is worse). The paint was only one day old but held good.

More test

results

In general, the adjustable screen with the hinge performs well. There was not

yet time for an off-road drive, but it performed well on minor bumps like

driving up the sidewalk. The only time when I could hear some noise from the

hinge was when I drove full speed over some speed bumps.

I noticed that mounting the brackets on the 4th screw of the mould rather than

on the 3rd, and the increased height of the screen in general because of the

hinge, resulted in much more space on the inside of the screen. This allows me

to put the wing nuts on the inside where they are less obtrusive than on the

outside. The extra space also allows the screen to be adjusted downwards without

the wing nuts hitting the top of the headlamp structure. They actually move over

the stock screen.

One negative point needs to be noted: The higher screen takes a significant part

of the wind away from the helmet. That's good, right? But it also means that

raindrops will stay longer on your visor, since they are no longer immediately

blown away by the wind. Now that the screen takes a larger part of your viewing

area, raindrops on the screen will be more annoying as well. I consider both

effects the consequences of luxury, but they need to be noted.

I have added a couple of shots below. Couldn't

find a nice background, so this will have to do until I'm back from my vacation

trip. The painted hinge starts blending in quite well with the stock screen. The

wing nuts on the inside are virtually invisible.

To be continued.......